Case Studies

Case Studies

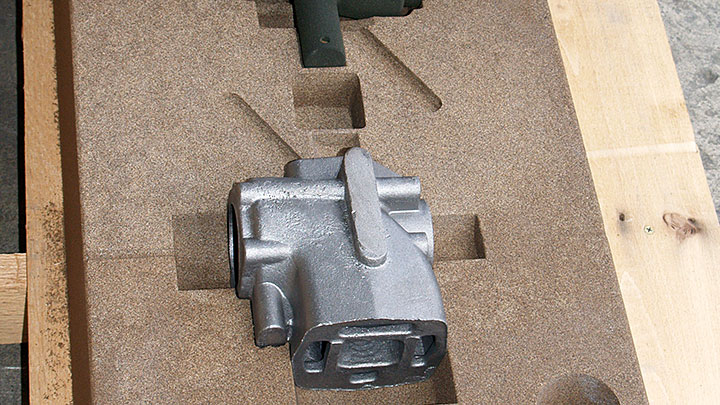

3D Printed Tooling Enables Quick-Turn Castings to Reduce Downtime

Demir Engineering invested in binder jetting for quick-turn metalcasting rapid replacement parts that limit expensive downtimes

Faster Deliveries and Flexible Production with Binder Jetting

How Wirco’s investment in sand 3D printing technology paid off in speed, precision, and flexible manufacturing solutions

Case Study: Wirco

3D Printed Tooling Enables Quick-Turn Castings to Reduce Downtime

Demir Engineering invested in binder jetting for quick-turn metalcasting rapid replacement parts that limit expensive downtimes

Case Study: Demir Engineering

Single-Piece Bike Frames Cast in Aluminum with 3D Printed Molds

Binder jetting helps produce a more confidence-inspiring ride without welds while enabling customizations to expand access

Case Study: Heavy Bikes

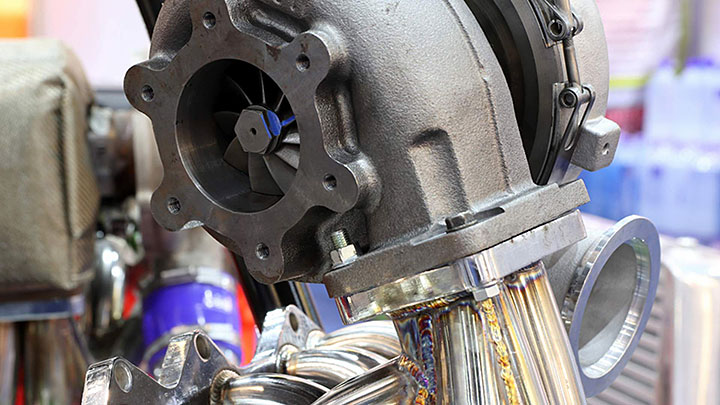

Shorter time to market and agility in production with sand binder jetting.

Döktas, the first foundry in the world to use ExOne S-Max Pro, leverages 3D printing for rapid prototyping and serial production

Case Study: Döktas

Efficiency and Precision through Sand 3D Printing in Iron Casting

Ekstrametal delivers top-quality cast parts by 3D printing molds and cores for rapid prototyping, short series productions, and GJV-450 machining fixture.

Case Study: Ekstrametal

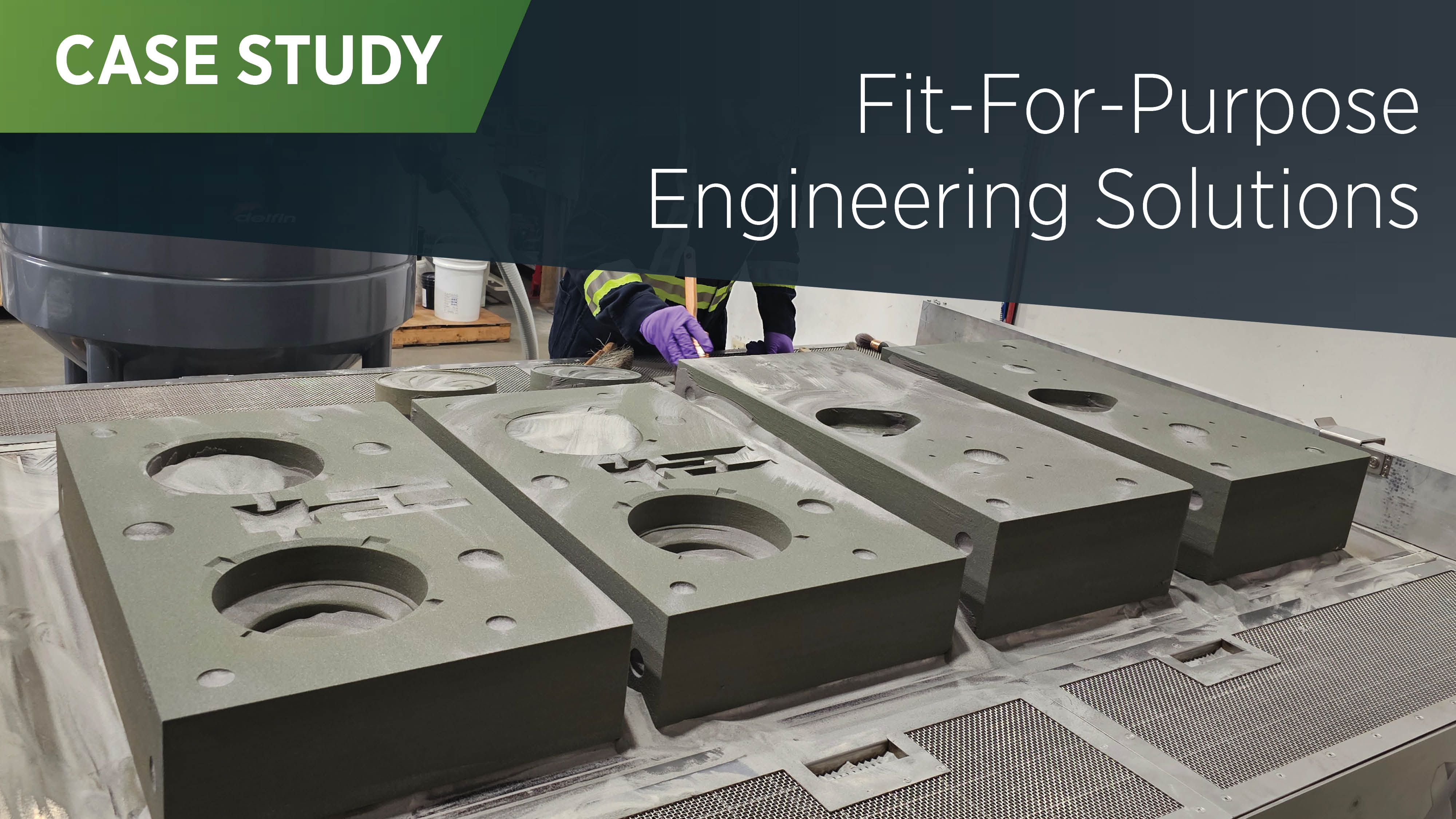

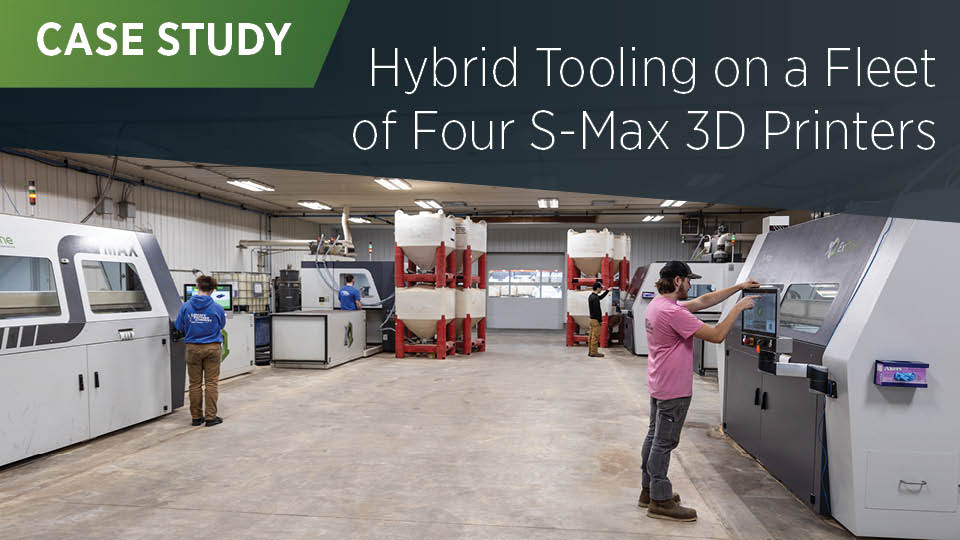

Traditional Pattern Shop Users Binder Jetting for Hybrid Tooling

Liberty Pattern adopt binder jet 3D printing at its facility in Iowa for complex core production and quickly grows to fleet of four machines

Case Study: Liberty Pattern

Indian Steel Foundry Solved Complex Castings with Sand Binder Jetting

Digital casting with ExOne S-Max® 3D printer enables KSB in India to drastically reduce lead times, improve part quality, and lower production costs

Case Study: KSB India

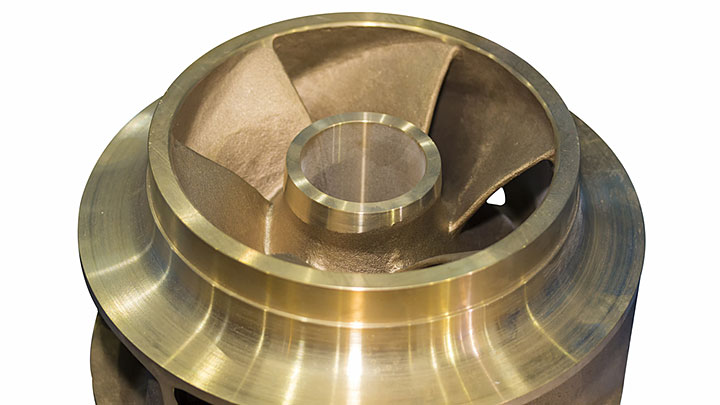

Rapid and cost-effective casting of complex impellers

Speed 3D Mold accelerates delivery time of a complex casting & achieves efficient, low-volume production with sand 3D printing

Case Study: Speed 3D Mold

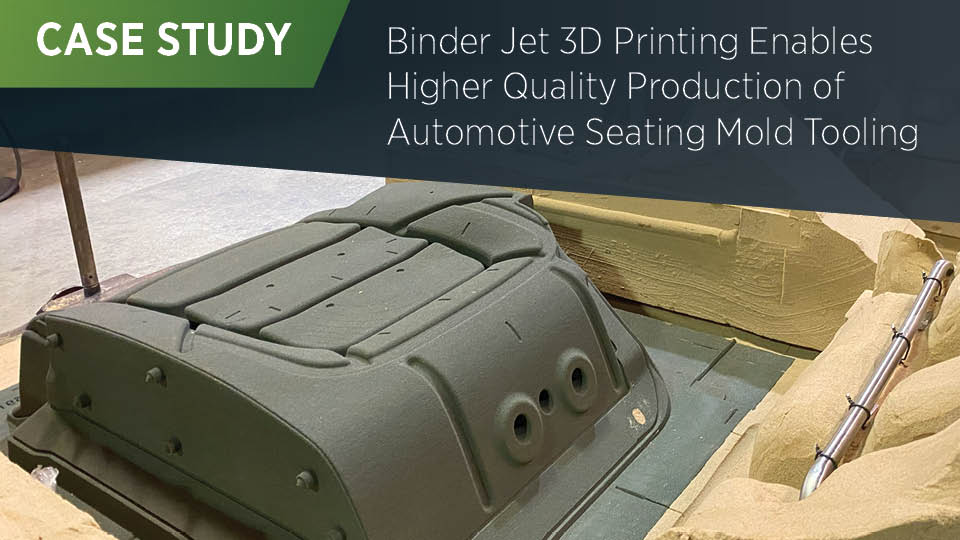

Binder Jetting for Higher Quality Automotive Seating Mold Tooling

Millions of automotive seats benefit from 3D printing technology at Dundee Castings’ to deliver updated tooling designs

Case Study: Dundee Castings

3D Printing Solutions for High-Scrap Assembled Cores

Kore Mart adopts S-Max® binder jet sand 3D printing system for top-quality cores that eliminate complex assemblies - even at serial production levels

Case Study: Kore Mart

Looking Ahead to the Next 150 Years with Binder Jet 3D Printing

Waupaca Foundry fuses tradition and technology by bringing binder jet sand 3D printing in-house

Case Study: Waupaca Foundry

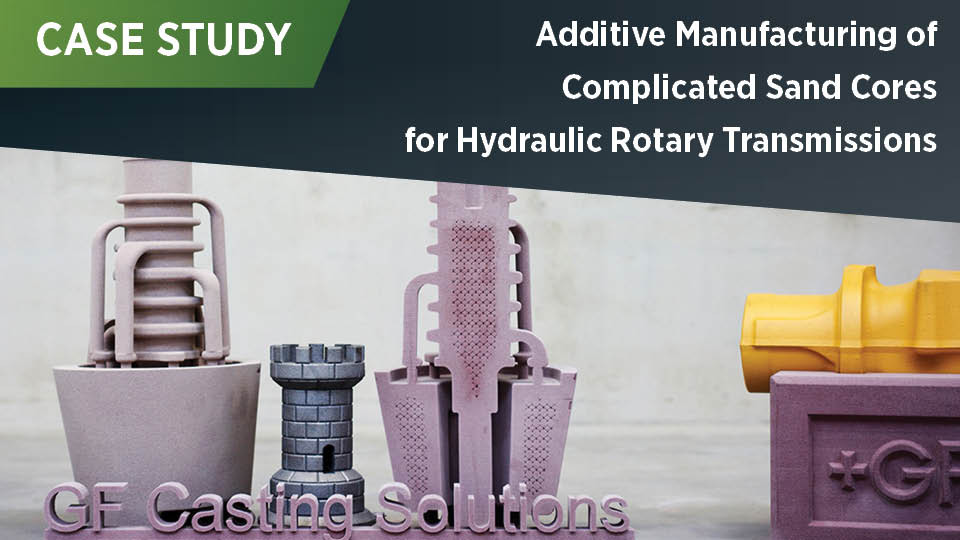

Georg Fischer Casting Solutions Leipzig consolidates 12 shot cores into one printed core

In addition to improving the core quality, time-intensive and laborious core assembling and fettling steps are eliminated.

Case Study: GF Casting Solutions Leipzig

Reverse Engineering and Topology Optimization with 3D Sand Printing

Replacement of a welded steel agricultural machine construction with a topology optimized casting within one week

Case Study: ÖGI (Austrian Foundry Institute)

Topology Optimized Spring Cup for Rail Vehicles

An award-winning research project of topology optimization enhancement with 3D sand printing for a lighter and longer lasting spring cup for rail vehicles

Case Study: MFL and ÖGI

Successful European Start-Up Supports 3D Printing for Foundries and Beyond

A completely digital workflow built around the ExOne S-Max® enabled start-up Zalewa Tec to quickly establish itself as a premium manufacturer of sand molds and cores

Case Study: Zalewa Tec

A Century of Experience Embracing Disruptive Metalcasting Technology

Grede, a 100+-year-old iron foundry, leads 3D printing innovations with serial core production

Case Study: Grede

Digital scanning and S-Max 3D printer create casting of obsolete cylinder head

Speed 3D Mold uses binder jetting to cast a replacement gray iron cargo ship engine component without the cost and lead time of traditional tooling

Case Study: Speed 3D Mold

Complex Aircraft Door Hinge Cast in Magnesium with 3D Printed Core

Ventana optimizes the design of an aircraft door hinge to be cast in magnesium for significant weight savings and performance improvement

Case Study: Ventana Group

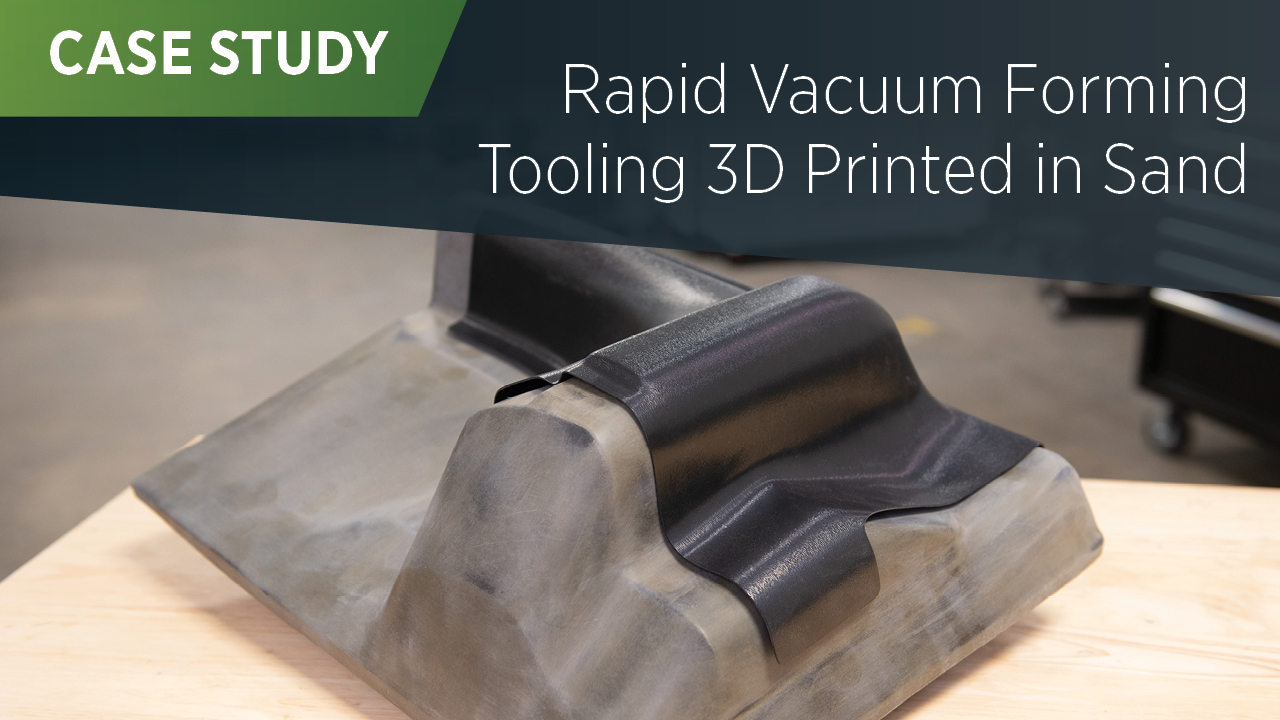

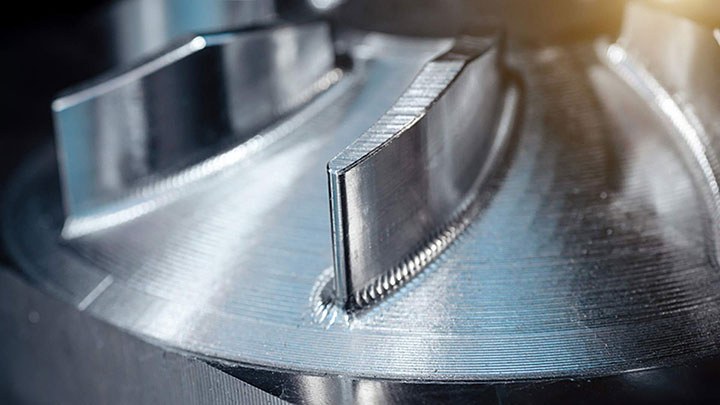

X1 ThermoForm Sand Tooling Proves Durability in Production

Original Appearance Manufacturing get products to market faster with cost-effective, precise, and durable rapid 3D printed sand tooling

Case Study: OAM X1 ThermoForm

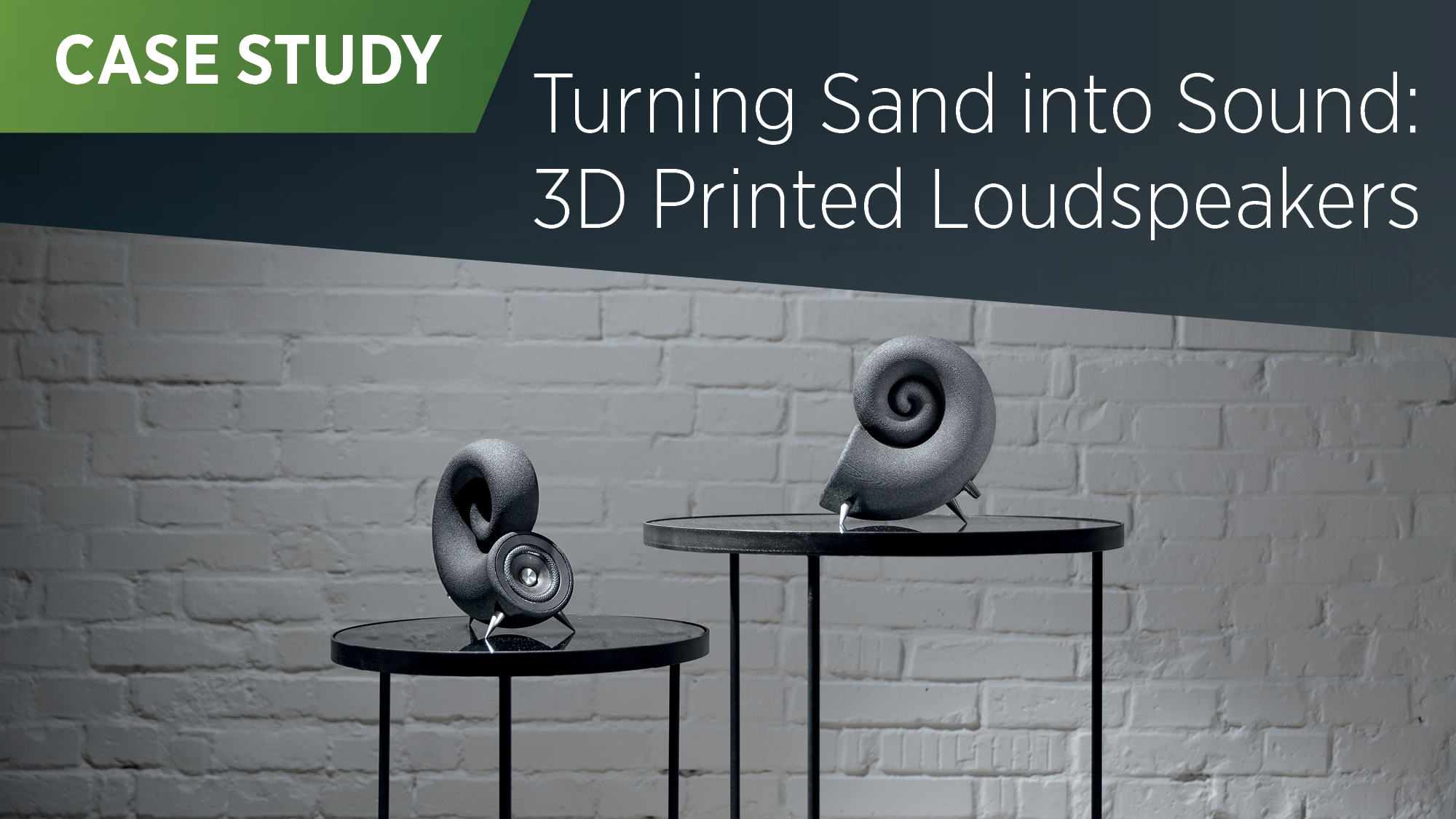

Turning Sand into Sound: 3D Printed Speakers

How a small startup in Czechia is challenging the giants of the audio industry with the help of 3D printing

Case Study: Deeptime

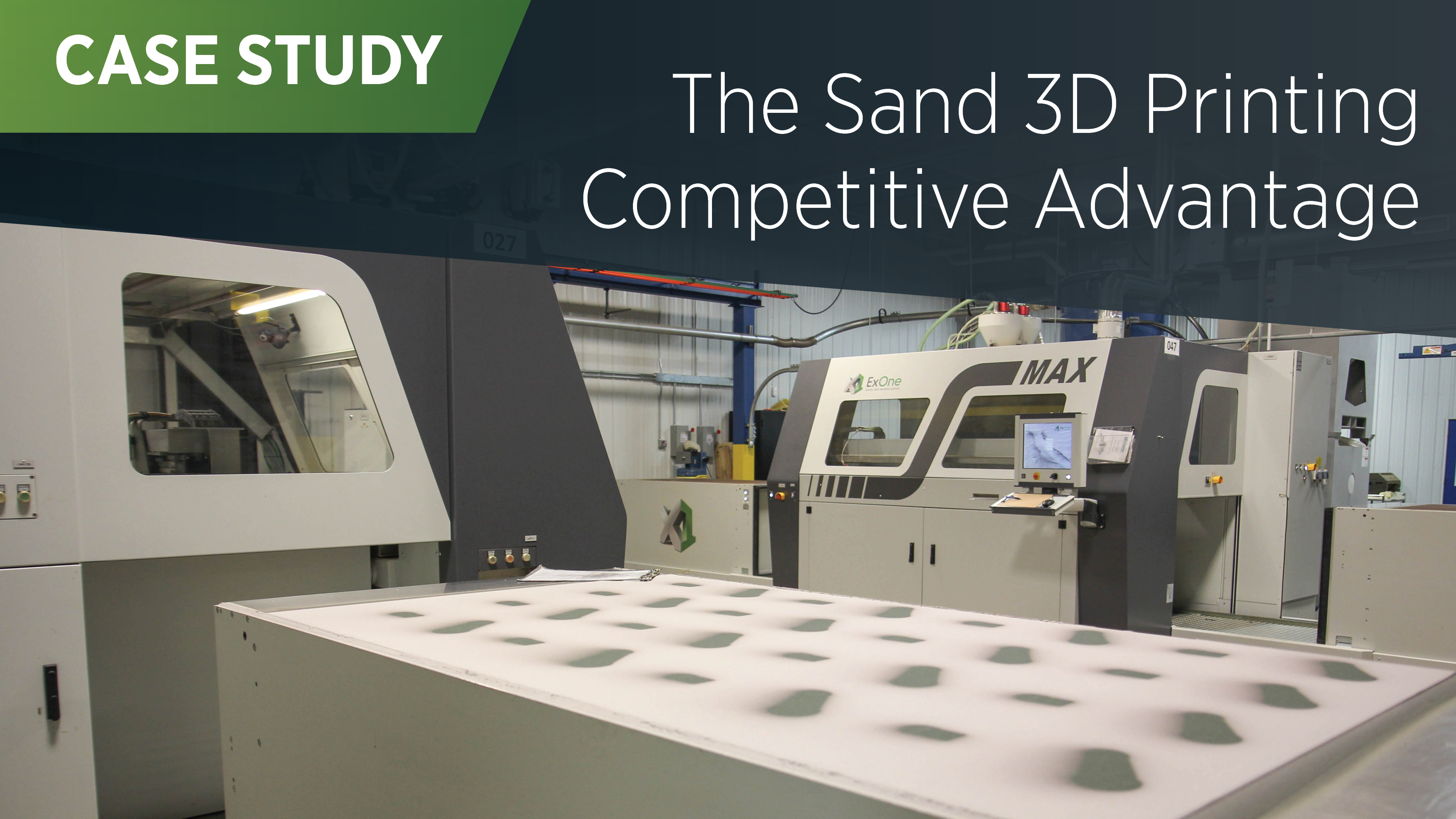

3D Printing Quality Molds Cores Provides Competitive Advantage

Hoosier Pattern embraced additive manufacturing as the first pattern shop in North America to own and operate a sand 3D printer in-house. Today they have four ExOne binder jetting systems.

Case Study: Hoosier Pattern

Global Foundry Group Innovates with Sand 3D Printing to Grow Business

With nine decades of experience in sandcasting innovation, Kimura Foundry America places sand binder jetting at the core of its business to deliver top-quality rapid prototypes.

Case Study: Kimura Foundry America

Innovative and Sustainable: A Step into the Future with 3D Printing Technology

Eisengiesserei Mezger, a Swiss iron foundry, expanded its services with a highly automated 3D printing system from ExOne – making the jump into new markets.

Case Study: Eisengiesserei Mezger

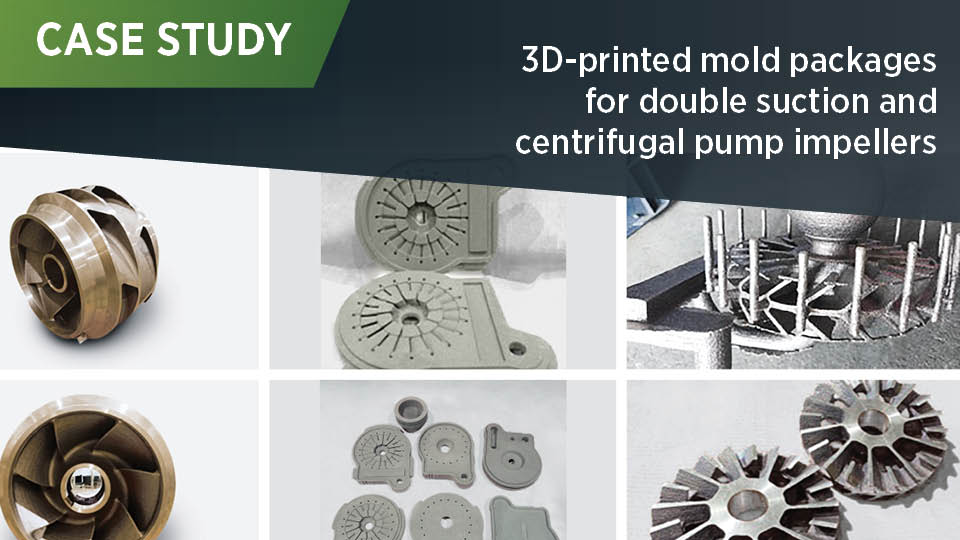

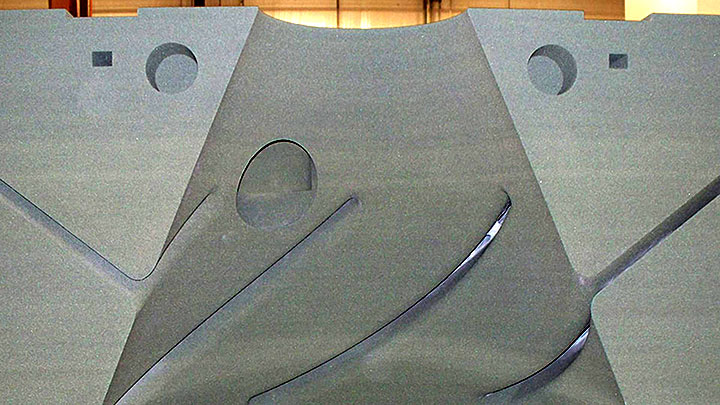

3D Printing Technology Dramatically Improves Manufacturing of Impellers

ExOne’s binder jetting printing technique simplifies production at the world’s leading water technology company, Xylem.

Case Study: Xylem Water Solutions Manufacturing AB

Humtown Products and ExOne

How 3D printing transformed a family-owned manufacturer.

Case Study: Humtown Products

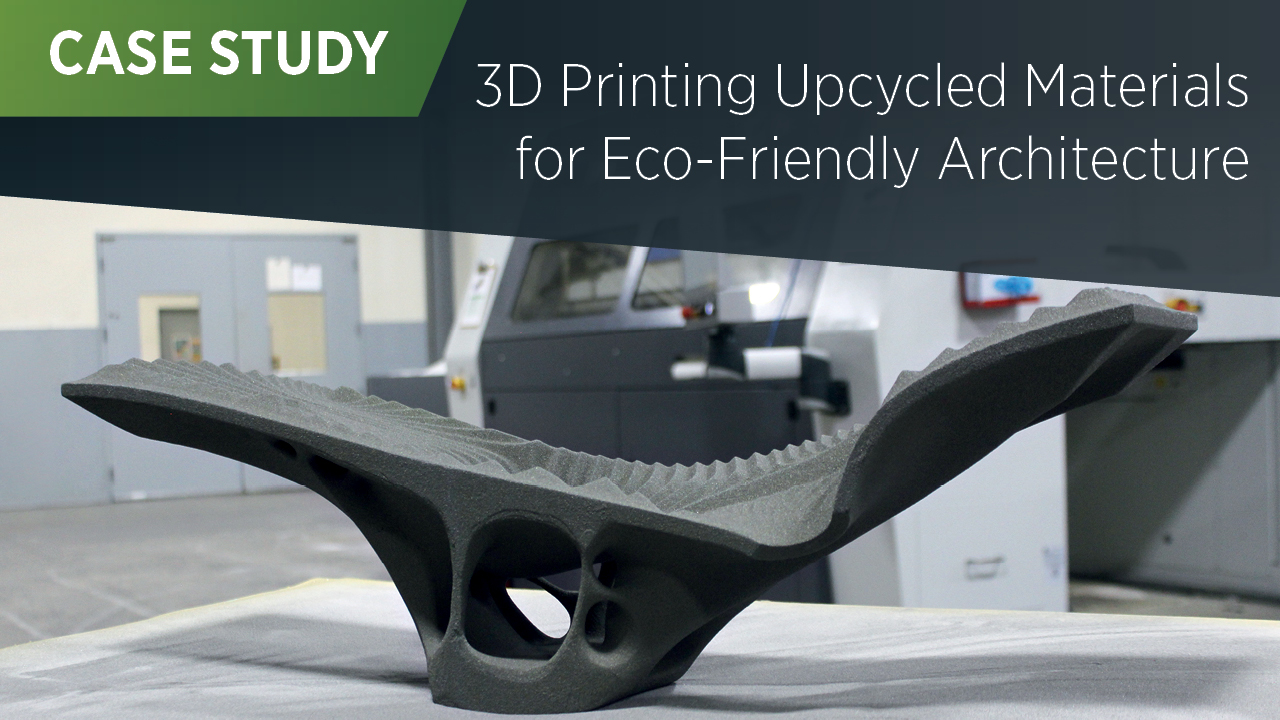

Reinventing Eco-Friendly Architecture and Upcycled Materials with ExOne Binder Jetting

Carnegie Mellon University School of Architecture is shaping the future of building design with 3D printing of concrete and other recycled materials

Case Study: CMU School of Architecture

New Perspectives Through 3D Printing

The prototype casting company Grunewald in Bocholt, Germany, invested in an ExOne sand 3D printer at the end of 2018. After more than a year, the payoff has been substantial.

What is Binder Jetting?

Binder Jetting is an additive manufacturing process in which a liquid binding agent is selectively deposited to join powder particles.

Fixture Manufacturer

Additive manufacturing offered a global kitchen and bath fittings manufacturer a faster way to develop new products.

German Automaker

German automotive manufacturer needed a way to quickly and economically produce complex prototypes.

Sand Mold Casting Applications

3D Printing Molds and Cores for Sand Casting Offers Design Freedom and Improved Efficiency

Standard Alloys

Manufacture a 57 inch impeller without a core box with ExOne's rapid casting process.

US Navy Compression Pumps

Reverse engineer compressor pump castings with 43 week reduction in lead time and 40% cost savings.

Select Filters Cancel

Applications

Select All

Industries

Select All

News & Events

Select All

Resources

Select All

Systems

Select All

Technology

Select All

.PNG?ext=.png)