Sand 3D Printing Success Stories

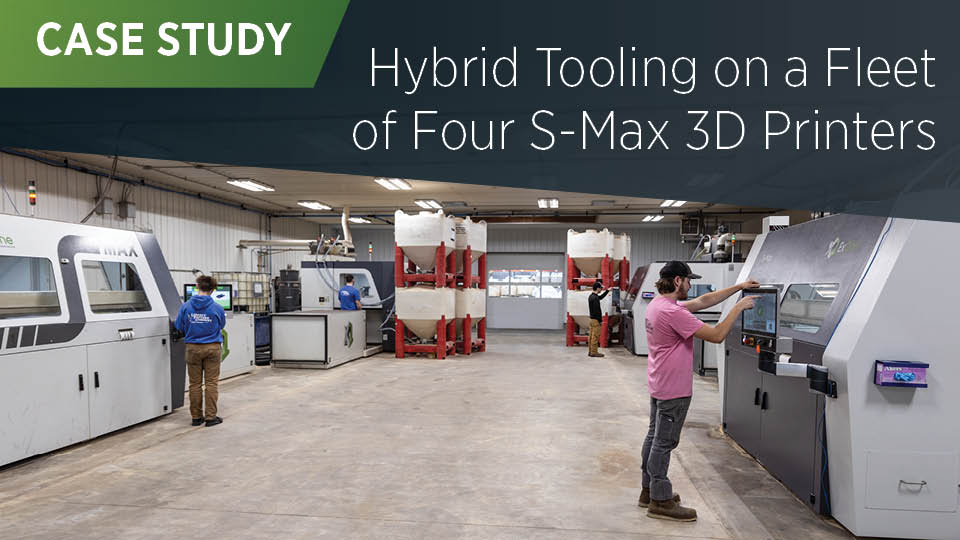

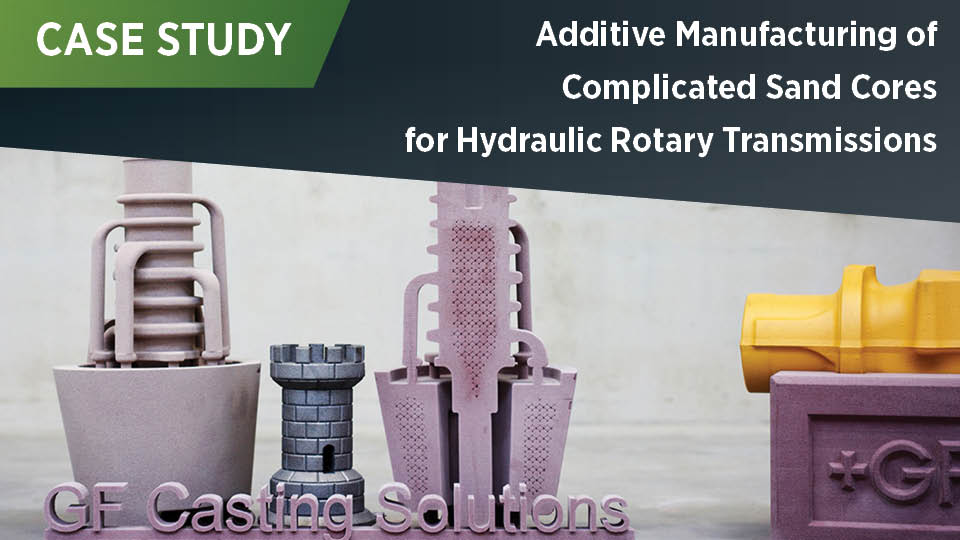

Foundries are using ExOne binder jet technology to dramatically cut lead times, eliminate scrap, and reduce assembly labor needs while casting complex designs with a digital workflow

Bring a Sand 3D Printer In-House

ExOne binder jetting can help foundries reduce delivery times and labor requirements. Learn more about the cost of bringing binder jet 3D printing in-house.

GET A MACHINE QUOTE

OneCast Design & Engineering

Our experts pair virtual design and casting simulation with 3D printed mold and core packages for done-in-one pour complex casting development.

ONECAST SERVICES

Find 3D Printing Services

Looking for a provider of premium sand molds and cores for your complex or quick-turn metalcasting project? Our network of 3D printer owners can help.

.PNG?ext=.png)