- Home

- Binder Jetting Resources

- Blog

Sand 3D Printing Pillar Page

Guide to Binder Jet Sand 3D Printing for Foundries

Guide to Binder Jet Sand 3D Printing for Foundries

A Complete Overview of Sand 3D Printing in Metalcasting

Foundry 3D Printing: Sand Binder Jetting

As the casting industry continues to evolve under global competition and changing economic conditions, sand 3D printing has revolutionized the foundry industry, transforming what’s possible with sandcasting.

Many sandcasting markets are struggling to keep up with demand at a time when reshoring initiatives and increased defense spending are leading to robust metalcasting expansion forecasts. According to the American Foundry Society , the number of metalcasting facilities in the U.S. has shrunk by more than 70% over the past seven decades, while a report from European Foundry Federation showed a year-over-year decrease of nearly 3% in the number of people employed in the foundry industry.

Binder jet additive manufacturing technology enables foundries to produce complex sand molds and cores with unprecedented precision, speed, and design freedom, enabling a more efficient and labor-effective business model. Foundries adopting sand 3D printing are discovering how the technology not only reduces lead times and costs, allowing a new approach to mold making and rapid prototyping but also enables entirely new design possibilities that can expand what’s possible to deliver with traditional sandcasting methods.

What is Sand 3D Printing?

Sand 3D printing is a binder jet additive manufacturing process that creates three-dimensional sand structures by selectively binding sand particles using liquid binding agents. Also known as 3D sandcasting or digital castings, sand binder jetting is a digital manufacturing technology that builds sand molds and cores layer-by-layer directly from CAD files, eliminating the need for traditional pattern making and tooling like coreboxes.

The technology behind 3D printed sand

Sand 3D printing utilizes binder jetting technology, where a printhead deposits liquid binder onto thin layers of powder material – in this case, sand, although the process is also used to produce metal, ceramic, and composite parts.

The process begins with spreading a uniform layer of sand, typically 0.5 mm (500 μm) or smaller, across the print bed. A precision printhead then selectively deposits binder material in patterns corresponding to each cross-section of the digital model. After each layer is completed, the build platform lowers, and a new layer of sand is spread on top. This process continues until the entire part is built.

The sand 3D printing process is compatible with both silica and ceramic sands with specific particle size distributions and flow characteristics optimized for the printing process. Sand characteristics, layer thicknesses, and software optimization enable exceptional surface finish and dimensional accuracy of the resulting prints.

Types of sand 3D printing binders

While sand 3D printing systems are generally categorized by their build volume and print speed, the main differentiation in the process is the binder system used for your application. The choice of binder system is crucial as it directly influences the strength, surface finish, and thermal stability of the printed molds and cores.

Furan sand 3D printing

Furan binder is among the most widely used in industrial sand 3D printing. The furfuryl alcohol-based binder is activated with acid catalysts. The resulting chemical reaction creates strong, durable molds and cores through a cure-in-box workflow. 3D printing with furan binder is particularly valued for its flexibility to create high-strength cores and molds in a variety of silica and ceramic sands suitable for casting in a wide range of metals including aluminum, magnesium, iron, and steel.

Phenolic binder jet 3D printing

Cold Hardening Phenolic (CHP) binders are another common choice for sand 3D printing, especially for applications where ease of desanding is a priority. These alkaline phenolic resoles are cured with esters and require a post-curing step at elevated temperatures. CHP binders are known for their ability to handle complex geometries while still providing sufficient strength during casting. Their compatibility with many sand types makes them versatile, and the ease of sand removal after casting is a significant advantage for foundries looking to reduce desanding labor.

Hot Hardening Phenolic (HHP) binders, in contrast, are acid-cured systems that also require post-curing but offer superior dimensional stability at high temperatures. These binders are ideal when the 3D printed sand cores must maintain their shape under thermal stress, such as during the casting of ferrous alloys. They deliver excellent mechanical strength and are compatible with a wide range of silica and ceramic sands, including both coarse and fine grain types. HHP binders are typically selected when core integrity at elevated temperatures is non-negotiable.

Inorganic foundry 3D printing

Inorganic binders represent an evolution of sand 3D printing technology to respond to growing environmental and workplace safety concerns. These binders are water-based and formulated with alkali-silicates and proprietary additives to enhance strength and high-temperature resistance. Unlike organic systems, inorganic binders emit no harmful gases during casting, making them ideal for foundries prioritizing environmental compliance and worker health. Their excellent thermal resistance also helps reduce the occurrence of casting defects related to gas evolution, such as porosity or veining.

The Benefits of Sand 3D Printing

Sand 3D printing offers numerous advantages over traditional sandcasting tooling methods, making it an attractive option for foundries to future-proof their business. Below is a brief overview, but learn more by downloading our tipsheet compiling 10 Reasons to Cast Metal with Sand 3D Printing.

Reduce lead times with 3D printed sand

The combination of eliminated tooling requirements, rapid printing speeds, and streamlined workflows dramatically reduces lead times from design to first casting. Projects that might require months using traditional methods can often be completed in weeks or days using sand 3D printing.

This dramatic shortening of lead times enables foundries to respond quickly to customers, reduce inventory requirements, and improve overall supply chain responsiveness. Rush orders and emergency repairs become much more manageable with sand 3D printing capabilities and offering rapid prototyping capabilities opens new business opportunities.

Solve foundry labor shortages with sand 3D printing

Keeping foundry operations fully staffed is an ongoing challenge. Reducing reliance on highly manual pattern-making and skilled core assembly with digital workflows lightens the load on limited staff. Production automation built around sand 3D printers in casting workflows empowers a leaner, more agile workforce to do more with less - improving throughput without compromising quality. Foundries can redeploy skilled workers to higher-value tasks while the printers handle mold and core production.

Streamline casting workflows with the dimensional accuracy of 3D printed sand

Modern sand 3D printing systems achieve surface finishes and dimensional accuracies that rival or exceed traditional sandcasting methods. Fine layer resolution and precise binder deposition enable smooth surfaces and sharp feature definition without the limitations imposed by pattern draft angles or core shifting. Learn more about the dimensional tolerances of 3D printed sand in this AFS research project.

Benefits are also often seen in downstream operations as 3D printed sand molds and cores produce castings with high dimensional accuracy that often require less post-processing, optimizing machining time and tool life.

New design freedoms and complexity with sand binder jetting

Traditional sandcasting requires draft angles, uniform wall thicknesses, and careful consideration of parting lines. Sand 3D printing eliminates these constraints, enabling the production of complex internal geometries, undercuts, and intricate features that would be impossible or extremely difficult to achieve through conventional methods.

Internal cooling channels, complex core configurations, or identifying features can be integrated directly into the design without additional assembly operations. This design freedom enables engineers to optimize parts for performance rather than manufacturability, leading to lighter, stronger, and more efficient components.

Expand business opportunities with sand 3D printing

Traditional sand casting requires extensive tooling including patterns, core boxes, and gating systems. These tools represent significant capital investment and lead time, particularly for complex geometries. Sand 3D printing eliminates tooling requirements, enabling direct production from digital files.

This elimination of tooling is particularly beneficial for low-volume production, custom parts, and complex geometries where tooling costs would be prohibitive. Sand binder jet 3D printing enables the economical production of single parts or small batches without the need for expensive tooling amortization.

How is Sand 3D Printing Used in the Foundry?

Sand 3D printing has revolutionized castings by offering flexibility, speed, and precision in creating molds and cores. Binder jet additive manufacturing technology eliminates many traditional constraints while opening new possibilities for designers and manufacturers. Here's a comprehensive look at how sand 3D printing is transforming foundry operations across various applications.

Rapid Prototyping in the Foundry with Digital Sand

Sand 3D printing enables foundries to pursue new business opportunities and expand customer relationships by offering rapid prototyping to quickly validate designs and test casting concepts without the traditional tooling investment. Engineers can move from a digital design to a physical prototype in a matter of days rather than weeks or months. With rapid prototyping capabilities, foundries enable immediate feedback on castability, dimensional accuracy, and surface quality. The ability to iterate quickly helps identify potential issues early in the development process, ultimately saving time and reducing costs in the overall product development cycle.

3D Printing Enables Fast Casting Iterations for Product Development

The digital nature of sand 3D printing makes design iterations fast and cost-effective. Where traditional tooling would require weeks to modify, sand 3D printing allows changes to be made directly in the CAD file and printed within hours. This agility is crucial for product development teams working under tight deadlines or responding to customer feedback. Multiple design variants can be tested simultaneously, and performance comparisons can be made quickly to optimize final design choices. This iterative approach leads to better products and faster time-to-market.

3D Printing Eliminates Assembly Through Core Consolidation

One of the most significant and commonly used advantages of sand 3D printing is the ability to consolidate multiple traditional cores into a single printed component. Cores that require multiple core segments to be produced and then assembled can be consolidated into a single 3D printed sand core. This consolidation reduces assembly time and labor, eliminates potential alignment errors, and often improves the overall casting quality by reducing the number of interfaces where defects can occur. Complex internal passages that would require multiple assembled cores in traditional methods can now be printed as unified structures.

Complex Geometries Made Easy with Binder Jetting

Sand 3D printing enables the creation of geometries that would be impossible or prohibitively expensive with traditional sandcasting methods. By eliminating expensive tool making, 3D printed sandcasting supports the realization of undercuts, complex geometries, or thin-walled structures. Internal channels, organic shapes, and intricate details that would require complex core assemblies can now be printed directly. This capability opens new design possibilities for engineers, allowing them to optimize parts for performance rather than manufacturing constraints. Heat exchangers, manifolds, and other components with complex internal passages particularly benefit from sand binder jetting.

Replacement Parts Fast with 3D Printed Sand

Sand 3D printing is ideal for producing replacement parts for legacy equipment where original tooling may be lost, damaged, or expensive to recreate. The ability to reverse-engineer existing components and produce replacements on demand helps extend the life of critical equipment. Sand binder jetting provides a solution without any tooling, saving foundries time and money while serving customers’ maintenance and repair operations where downtime costs are high and quick turnaround is essential.

One-Off and Low-Volume Castings with Sand 3D Printing

Digital sand 3D printing technology eliminates patterns and coreboxes, making low-volume and even one-off castings cost-effective. Where traditional tooling costs would be prohibitive, or impossible for customized parts where each casting may have unique features, foundries can use the flexibility of binder jet technology to take on short-run business and earn profits with parts on demand.

Using Sand 3D Printing for Serial Core Production

While often associated with prototyping, sand 3D printing is increasingly used in the serial production of cast components. Foundries use binder jetting for in-house, lights-out core production. Consolidated core geometries eliminate the need for assembly and the scrap from assembly errors – streamlining the entire casting workflow. Binder jet sand 3D printing’s flexibility allows for production scheduling that matches demand patterns without the inventory burden of pre-made tooling.

Foundries Finding Success with Digital Castings

3D printed molds and cores are the future of metalcasting, allowing foundries to pour increasingly complex geometries or design organic rigging to improve pour quality - all with lead times measured in days, not weeks. ExOne customers around the world are successfully implementing sand binder jetting to transform their businesses. See all our sand 3D printing success stories.

A week's worth of production sandcasting cores 3D printed in 18 hours

Many cores at Wirco were assembled  Sand 3D printing helps ease strenuous jobs and improve the environment for workers, making employment at the foundry more desirable. from multiple segments, requiring individual core boxes to produce individual parts that were then glued together. Some jobs even require skilled labor to place a wire between two core segments to provide additional strength. This manual assembly not only added to casting lead times, but also introduced the opportunity for inaccuracies and oversights in the process. With binder jetting, core designs can be consolidated into single-piece prints, eliminating the need for assembly and the scrap from assembly errors. Even when no other design optimization is done to the cores themselves, simply printing a monolithic core with binder jetting improved Wirco’s production process. One core with previous quality claims was 3D printed as one piece, creating a clean intersection without seams where two cores previously were assembled together. Download the case study to learn how the foundry increased production core throughput with sand 3D printing.

Sand 3D printing helps ease strenuous jobs and improve the environment for workers, making employment at the foundry more desirable. from multiple segments, requiring individual core boxes to produce individual parts that were then glued together. Some jobs even require skilled labor to place a wire between two core segments to provide additional strength. This manual assembly not only added to casting lead times, but also introduced the opportunity for inaccuracies and oversights in the process. With binder jetting, core designs can be consolidated into single-piece prints, eliminating the need for assembly and the scrap from assembly errors. Even when no other design optimization is done to the cores themselves, simply printing a monolithic core with binder jetting improved Wirco’s production process. One core with previous quality claims was 3D printed as one piece, creating a clean intersection without seams where two cores previously were assembled together. Download the case study to learn how the foundry increased production core throughput with sand 3D printing.

Sand 3D printing technology delivers updated seat mold tooling designs

Complex features are 3D printed into seat molds with ease. Here a void printed into a mold allows magnets to be inserted after casting.Millions of automotive seats and other interior components benefit from Dundee Castings’ investment in binder jetting to deliverupdated tooling designs. A Tier 2 supplier of premium, automotive seating molds to most of the world’s leading global automakers, the company needed to stay ahead of the technological curve to ensure the future of the business, partially driven by the changing dynamics of the labor market. By using binder jet sand 3D printing, the team improved consistency and quality, while eliminating the human error and tolerance stacking of multiple manual processes through digital sand production. New levels of intricacy are printed directly into designs that were previously unachievable, or only achieved through additional manual processes. Download the complete case study to learn about the features Dundee Castings prints into seat molds with binder jet 3D printing.

Complex features are 3D printed into seat molds with ease. Here a void printed into a mold allows magnets to be inserted after casting.Millions of automotive seats and other interior components benefit from Dundee Castings’ investment in binder jetting to deliverupdated tooling designs. A Tier 2 supplier of premium, automotive seating molds to most of the world’s leading global automakers, the company needed to stay ahead of the technological curve to ensure the future of the business, partially driven by the changing dynamics of the labor market. By using binder jet sand 3D printing, the team improved consistency and quality, while eliminating the human error and tolerance stacking of multiple manual processes through digital sand production. New levels of intricacy are printed directly into designs that were previously unachievable, or only achieved through additional manual processes. Download the complete case study to learn about the features Dundee Castings prints into seat molds with binder jet 3D printing.

Pattern shop adopts sand 3D printing and quickly grows to fleet of six machines

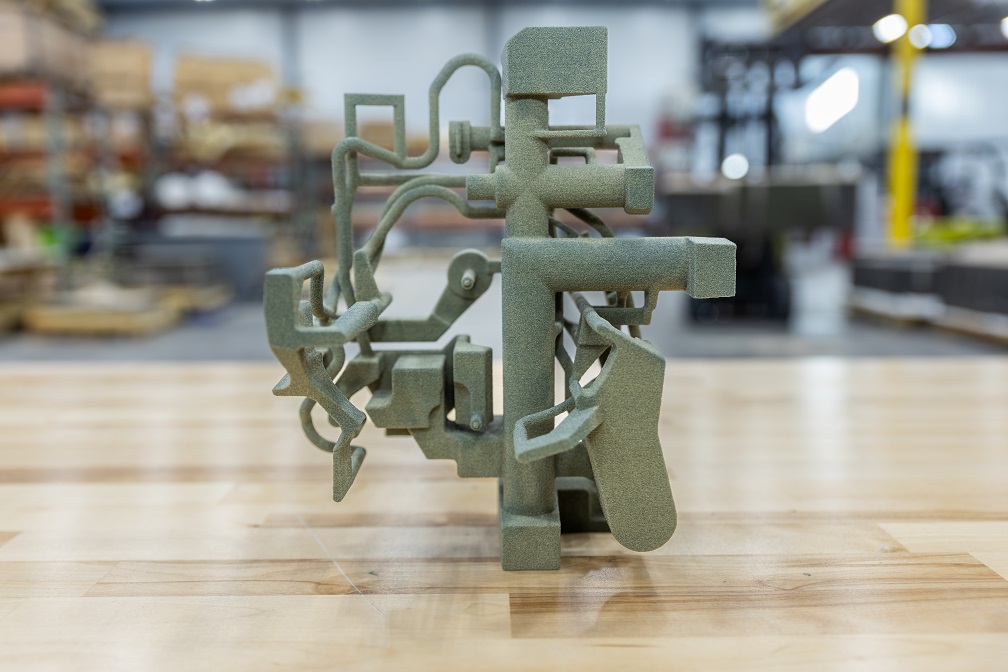

As a full-service pattern shop, Liberty Pattern saw the ever-increasing complexity This complex core for an aerospace application was 3D printed as a single piece at Liberty Pattern to replace a traditional assembly of over 20 pieces.

This complex core for an aerospace application was 3D printed as a single piece at Liberty Pattern to replace a traditional assembly of over 20 pieces.

of casting designs and required new innovations to complement the capabilities of its experienced patternmakers. Hybrid metalcasting is becoming a main offering, combining both traditional hard tooling for large mold sections and 3D printing for the complex internal features of applications. A quarter of the fleet’s capacity runs serial production jobs, while the flexibility of binder jetting allows the team to provide services to a wide range of customers. Traditionally an assembly of over 20 cores, the complex single-piece core for an aerospace application, pictured to the right, was 3D printed as one piece on the S-Max. Download the case study to learn about reduced-assembly sand cores 3D printed with binder jetting to produce hybrid tooling for the most complex castings.

.PNG?ext=.png)