Reinventing Eco-Friendly Architecture and Upcycled Materials with ExOne Binder Jetting

Reinventing Eco-Friendly Architecture and Upcycled Materials with ExOne Binder Jetting

Carnegie Mellon University School of Architecture is shaping the future of building design with 3D printing of concrete and other recycled materials

Read the Complete Story

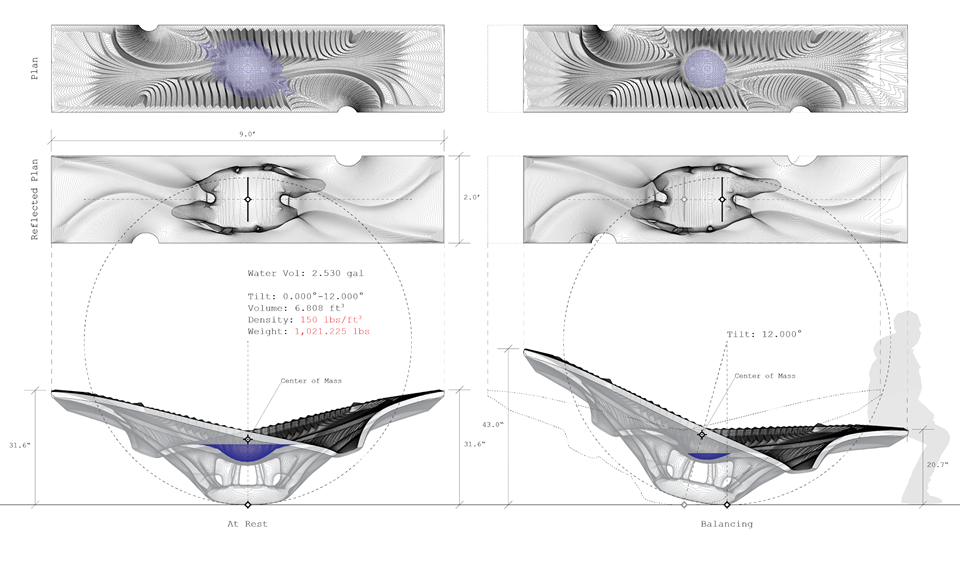

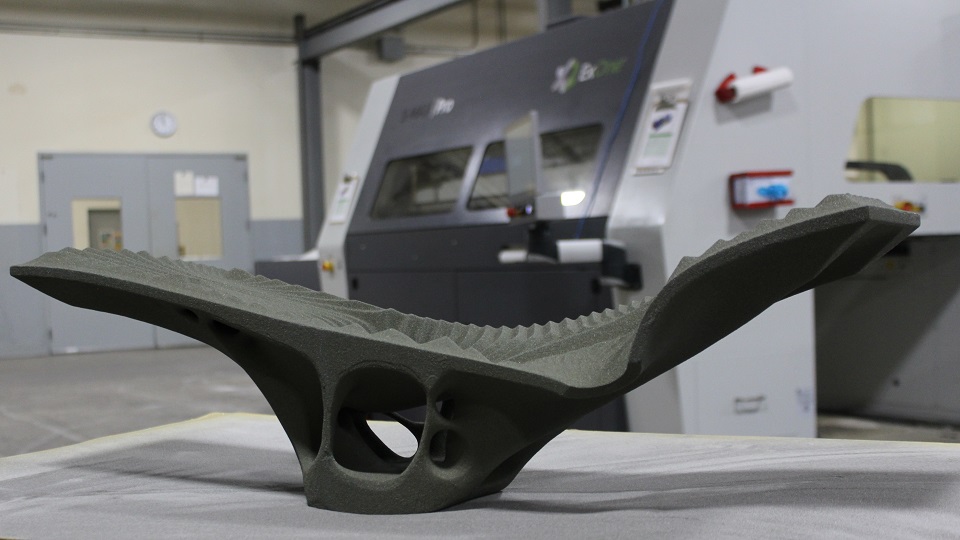

Learn How CMU's School of Architecture uses ExOne binder jet technology to 3D print cradle rockers that help reclaim nature in the Steel City with smarter architecture for stronger, healthier communities.

Download the Case study