EPIC Design - 3D Printing Elevated

Infiltrated 3D printed forms for architectural restorations, interior and exterior design,

and unique pieces of art.

EPIC Design technology produces durable, affordable, and extra-large designs with customizable surface textures and finishes for architects, artists, and designers

KEY FEATURES AND BENEFITS

- Speed: By printing directly from a CAD file, EPIC Design products offer faster turnaround times than traditional materials

- Cost: By starting with a cost-effective raw materials such as sand, infiltrating green parts with resin opens new design opportunities to a broad audience without the cost of traditional tooling, patterns, or machining

- Design Freedom: Without the limitations of manufacturability with traditional processes, 3D printing allows complex geometries and lightweight lattices to be printed layer by layer

- Flexibility: Whether metal plated, powder coated, or replicating plaster or leather, surface finish and coloration is tailored to your application.

What is EPIC Design?

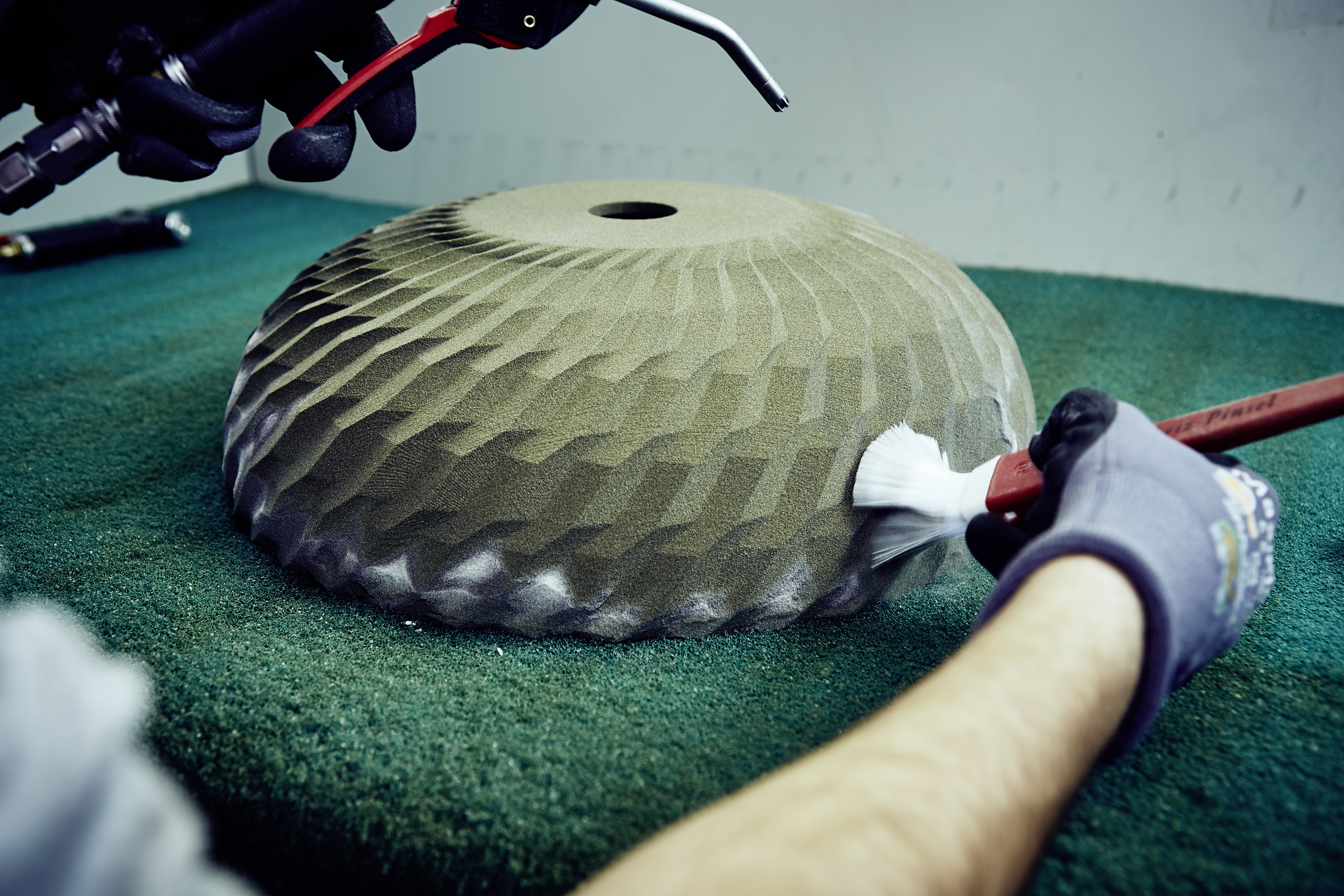

Traditional CNC machining lacks the capability to produce complex, organic designs and often requires long lead times and high tooling investments. Engineered Particulate Infiltration Composite (EPIC) Designs start by optimizing a digital model that can be 3D printed on an ExOne S-Max machine in under 24 hours without traditional manufacturing limitations. Green state parts are then transformed into durable, functional parts through a resin infiltration process. A range of surface finishes allow for customizations that are durable and rated for interior or exterior use and tailored to the design requirements. The technology is also used to create industrial tooling.

From architecture and restoration to art and consumer products, EPIC designs are used today as building components, statues, end-use decorative products, and speaker housings

The original capitol piece (top) was 3D scanned before being reproduced with ExOne sand 3D printing and processed with EPIC Design technology (middle). The final components were installed on the exterior of Bentley Hall at Allegheny College (bottom).

The original capitol piece (top) was 3D scanned before being reproduced with ExOne sand 3D printing and processed with EPIC Design technology (middle). The final components were installed on the exterior of Bentley Hall at Allegheny College (bottom).

Lattice structures are tested for strength (top) while patterning is investigated for more ecologically-friendly design (middle). Cradle rocking planters (bottom) were developed with ExOne EPIC Design technology.

Lattice structures are tested for strength (top) while patterning is investigated for more ecologically-friendly design (middle). Cradle rocking planters (bottom) were developed with ExOne EPIC Design technology.

Interested? Get Started Today!

Reach out to speak with an ExOne representative on how sand 3D printing can bring your EPIC Design to life.

Contact us