ExOne Global Holdings unifies ExOne and voxeljet

With this integration, the founders and pioneers of sand 3D printing are reunited. Sharing common roots, both companies now move forward together — improving product portfolio, strengthening global printing services and deepening aftermarket support.

Learn more

Inside the Pioneering Additive Manufacturing Journey of BMW and ExOne

Learn how ExOne’s binder jet 3D printing technology helps BMW make its sustainable manufacturing vision a reality in serial production.

Learn More

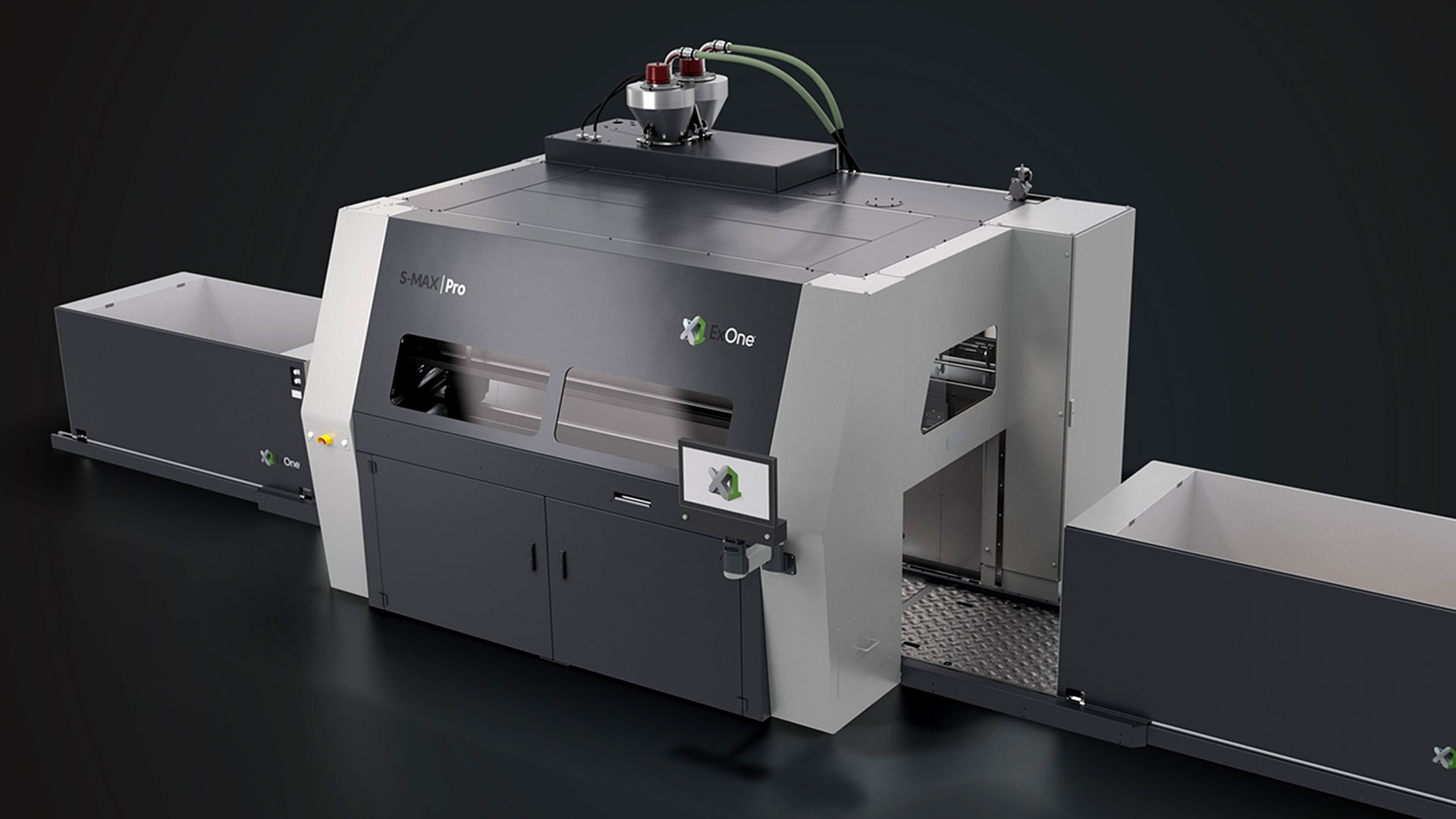

S-Max® Pro Production Sand 3D Printer

The S-Max® Pro delivers an industry-leading combination of speed and precision on a system that can process all ExOne binder systems for reliable production of complex cores and molds. Foundries are able to do more with integrated automation that enables lights-out manufacturing.

Learn More

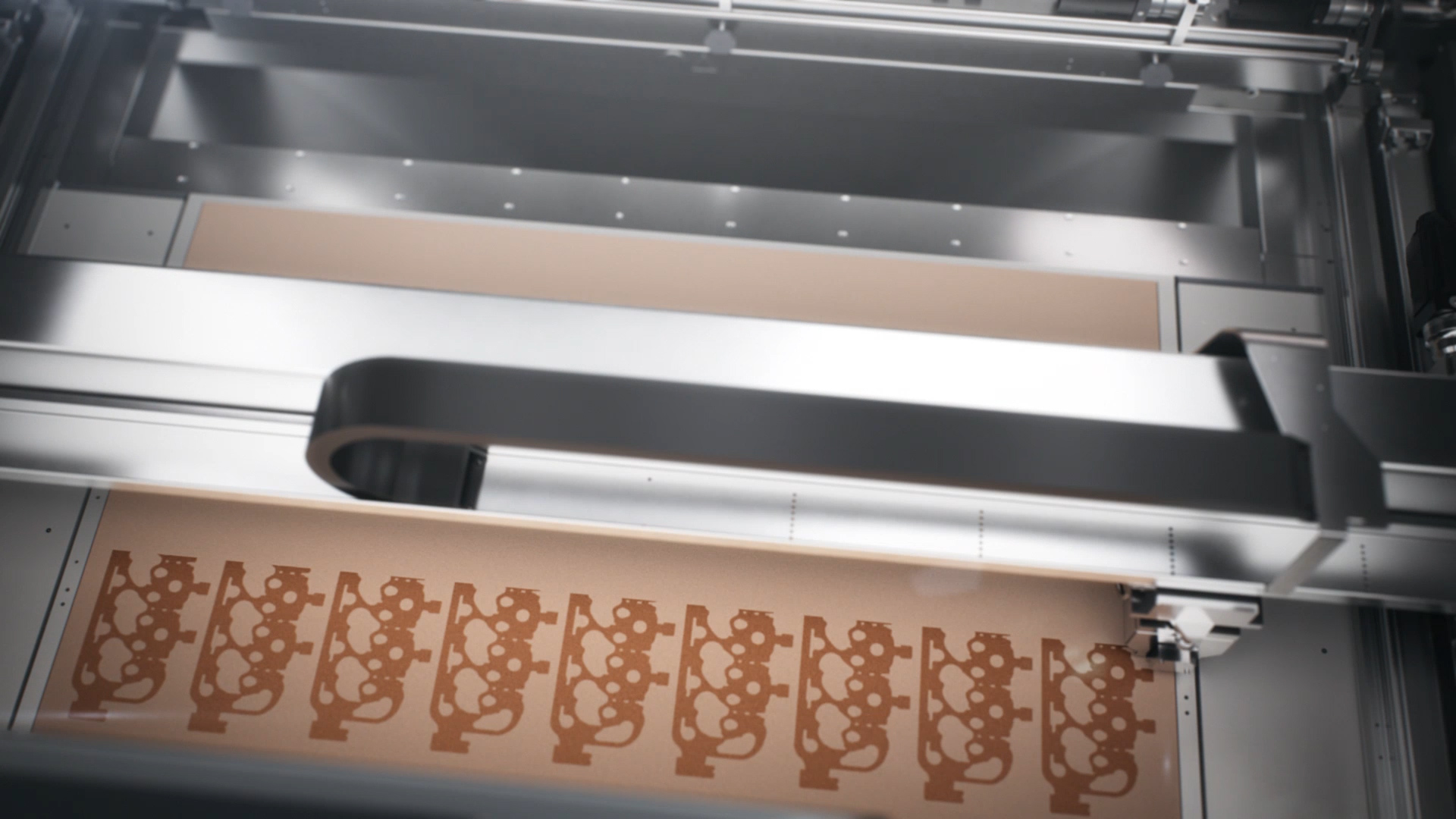

Binder Jet 3D Printing

ExOne industrial binder jet 3D printers enable a digital workflow to deliver complex designs with fast turnarounds for a range of applications from metalcasting molds and cores to rapid tooling.

Binder Jet 101Digital Metalcasting Experts, Foundry Partners

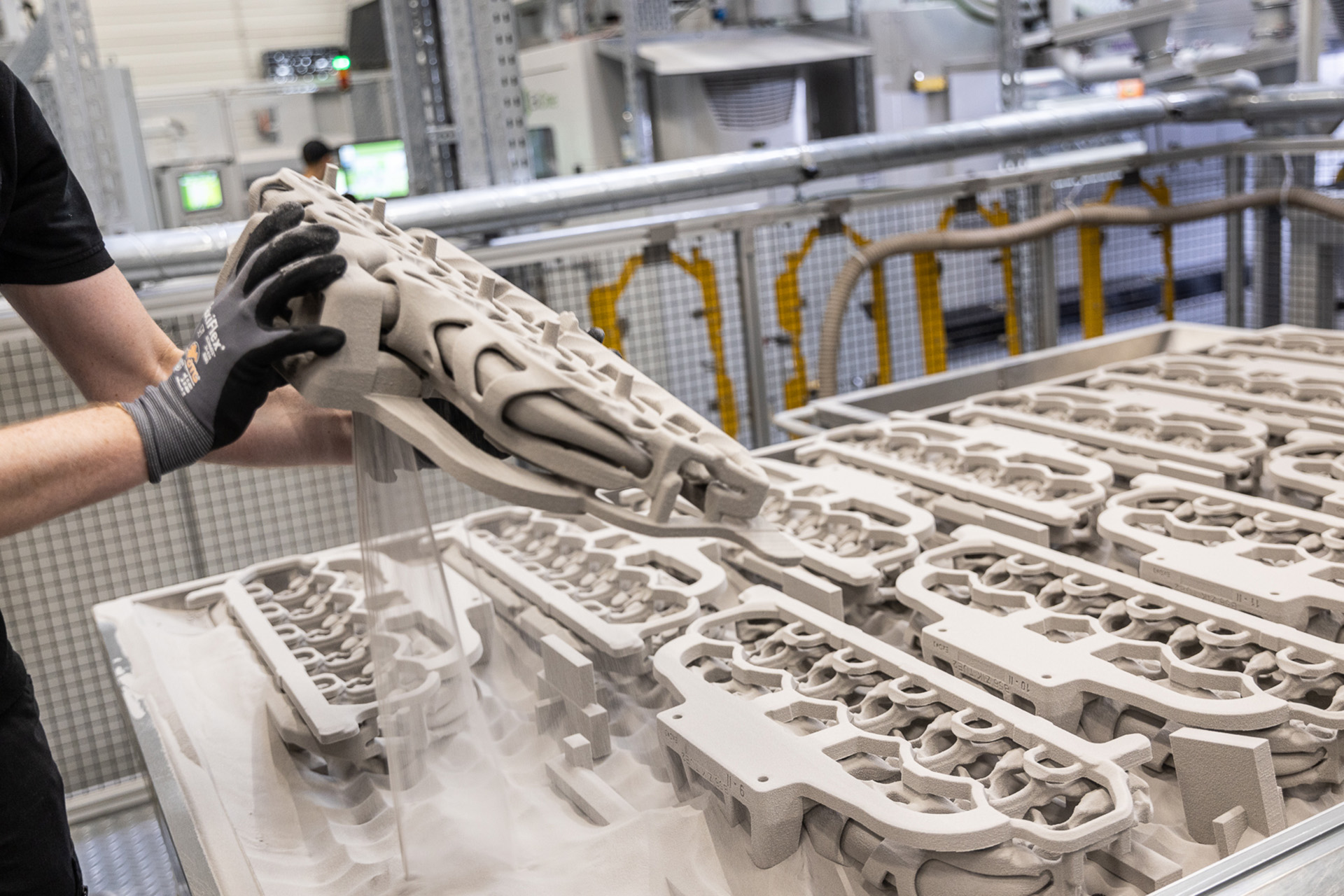

As a leader in additive manufacturing for over two decades, ExOne sand 3D printers have helped foundries and pattern shops transform sandcasting by eliminating the need for hard tooling. Our binder jet 3D printing technology enables digital foundries to produce previously impossible shapes, consolidate complex cores to reduce assembly, or iterate design changes without the time or investment of traditional tooling.

With a team of 3D printing and foundry experts, ExOne is committed to your success with binder jetting. Our team provides full systems and support, engineering services and casting simulation for high-value done-in-one pours, and on-demand 3D printing of complex molds and cores as well as infiltrated sand tooling for a variety of applications.

Sand 3D Printers

Foundry 3D printers from ExOne support sandcasting applications with enhanced designs and fast turnaround times. With a variety of systems to meet every production requirement and price, our binder jetting machines produce complex cores and molds without the cost and lead times of traditional tooling.

Foundry 3D Printing Systems

Materials & Binders

The leaders in 3D sandcasting, ExOne offers a variety of sand and binder combinations for both ferrous and nonferrous processes. From high-strength casting media to emission-free, defect-free inorganic binder, we tailor 3D printing with sand to your foundry’s needs.

Material FlexibilityKimura Foundry America

After all of our research on all of the 3D printer vendors in the world, we determined that ExOne printers are better and they have a very high-end technology, and very good print quality.

Dr. Yoya Fukuda, Ph.D.

.PNG?ext=.png)