- Home

- Binder Jetting Resources

- Blog

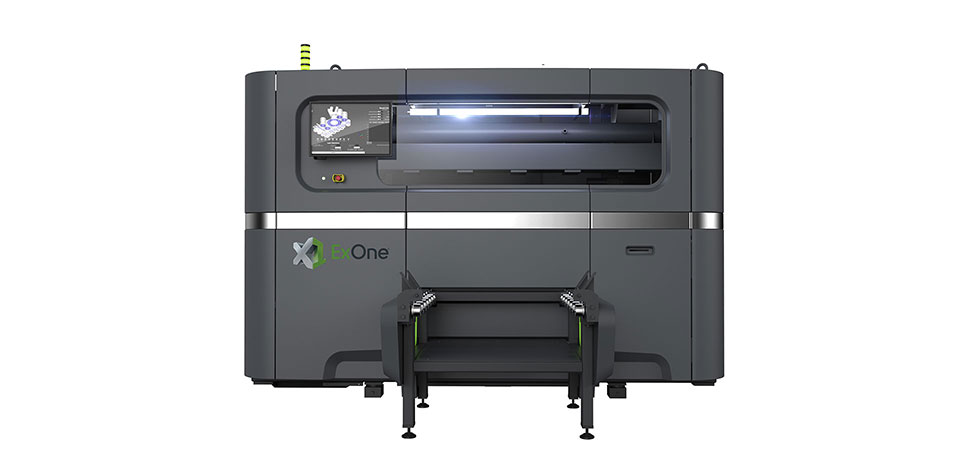

X1 160PRO™

ExOne Introduces New X1 160PRO™ Metal 3D Printer for High-Volume Production of Quality Parts

ExOne Introduces New X1 160PRO™ Metal 3D Printer for High-Volume Production of Quality Parts

ExOne Introduces New X1 160PRO™ Metal 3D Printer for High-Volume Production of Quality Parts

- Designed for throughput: The largest metal binder jetting system available, the X1 160PRO offers more than 2.5 times the build volume of competing systems for sale today

- Unparalleled material flexibility: Capable of 3D printing more than six qualified metal materials, plus ceramics, into dense and dimensionally accurate parts

- Featuring patented Triple ACT: This advanced new system for dispensing, spreading and compacting ultra-fine powders delivers industry-leading density and repeatability

- The tenth and largest metal 3D printer from ExOne: The trusted, global leaders in industrial binder jetting systems for sand, metal and ceramics

NORTH HUNTINGDON, Pa.--(BUSINESS WIRE)--The ExOne Company (Nasdaq: XONE), the global leader in industrial sand and metal 3D printers using binder jetting technology, today revealed the culmination of two decades of metal 3D product development with its tenth and largest metal 3D printer to date: the X1 160PRO.

Built for high throughput and large-part production, the new X1 160PRO metal 3D printer offers build dimensions of 800 x 500 x 400 mm, delivering 160 liters of total build volume volume ̶ large enough to produce investment cast parts used in the automotive, aerospace, and defense industries.

The open material system is capable of 3D printing six qualified metals, including the popular stainless steels 316L, 304L and 17-4PH, as well as some ceramics, into dense and reliable final parts using ExOne’s exclusive Triple Advanced Compaction Technology (ACT) system.

With print speeds topping 10,000 cm3/hour, depending on print material, the X1 160PRO is designed to deliver the best quality part at production speeds. The new system also features Industry 4.0 cloud connectivity and process-linking capabilities enabled by Siemens MindSphere.

“Our technology roadmap has been leading us to this machine for more than two decades,” said John Hartner, ExOne CEO. “At the same time, the X1 160PRO was also designed in response to growing demand from automotive, defense and aerospace customers. We’re incredibly proud of what this model means for the future of metal 3D printing and sustainable production of large metal parts without design limitations.”

The X1 160PRO joins ExOne’s growing family of metal 3D printers, which includes the Innovent+, an entry-level system used globally for research, design and small part production, and the X1 25PRO, a mid-size production 3D printer that is large enough for most metal parts manufactured today. The X1 25PRO begins shipping to customers this quarter and is slated to be shown for the first time in Europe this month at Formnext 2019 in Frankfurt, Germany. The X1 160PRO is slated to ship in late 2020.

Essential Triple ACT System for Volume Production

The X1 160PRO features ExOne’s exclusive and patented Triple Advanced Compaction Technology (ACT) system, which is critical to delivering consistent part density and repeatability across the entire build area when binder jet 3D printing.

Binder jetting is a method of 3D printing in which an inkjet prints a binding fluid onto a fine layer of powder, building a part, one layer at a time. ExOne’s Triple ACT tackles one of the biggest challenges of binder jetting metal powders to perfection: dispensing, spreading and uniformly compacting ultra-fine powders with an average particle size, or D50, of 9 microns. These powders’ cohesiveness makes them prone to caking and difficult to dispense. ExOne’s technology overcomes this challenge.

ExOne has extensive experience in metal binder jet 3D printing. The company launched the world’s first commercial metal binder jet system, the RTS-300, in 1998, followed by a new metal printer every few years. About half of the company’s binder jet printer systems installed worldwide are metal 3D printers. Additionally, the company operates the world’s most productive metal binder jet printing production facility at its headquarters outside of Pittsburgh.

This experience led to the development of the Triple ACT system for precisely controlling fine powders and delivering high part density and repeatability. Learn more at www.exone.com/tripleACT

About ExOne

ExOne is a global provider of 3D printing machines, 3D printed products, materials and services to industrial customers. ExOne's business primarily consists of manufacturing and selling 3D printing machines and printing products to specification for its customers using its installed base of 3D printing machines. ExOne’s machines serve direct and indirect applications. Direct printing produces a component; indirect printing makes a tool to produce a component. ExOne offers pre-production collaboration and print products for customers through its network of ExOne Adoption Centers (“EACs”). ExOne also supplies the associated materials, including consumables and replacement parts, and other services, including training and technical support that is necessary for purchasers of its 3D printing machines to print products. The Company believes that its ability to print in a variety of industrial materials, as well as its industry-leading volumetric output (as measured by build box size and printing speed) uniquely position ExOne to serve the needs of industrial customers.

Contacts:

ExOne Customers:

Sarah Webster

Global Marketing Director

+1 724 516-2336

sarah.webster@exone.com

ExOne Investors:

Deborah K. Pawlowski / Karen L. Howard

Kei Advisors LLC

+1 716 843-3908 / +1 716 843-3942

dpawlowski@keiadvisors.com / khoward@keiadvisors.com

.PNG?ext=.png)