- Home

- Binder Jetting Resources

- Blog

ExOne Announces Siemens as Inaugural Customer for All-New InnoventPro™ Entry-Level Metal Binder Jet

ExOne Announces Siemens as Inaugural Customer for All-New InnoventPro™ Entry-Level Metal Binder Jet 3D Printer

ExOne Announces Siemens as Inaugural Customer for All-New InnoventPro™ Entry-Level Metal Binder Jet 3D Printer

Global manufacturing innovation leader Siemens is the first of several customers to place an advance purchase for the InnoventPro 3L metal 3D printer

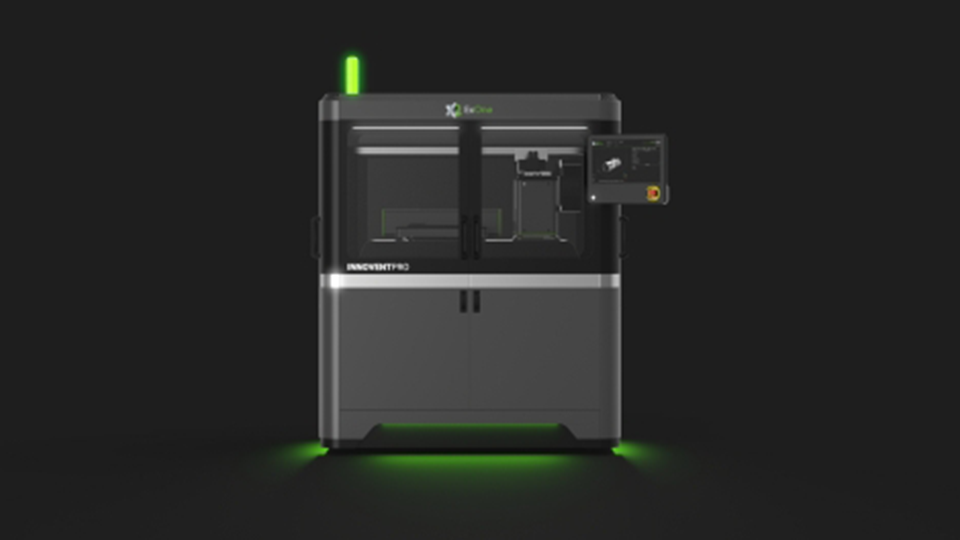

The InnoventPro is the world’s most advanced entry-level model for metal binder jetting — designed to take the easy-to-use features of the popular Innovent+ with patented Triple ACT advanced compaction technology and offer them with a bigger build area and the best speed and cutting-edge technology features of ExOne’s production-ready printers, such as the X1 25Pro® and X1 160Pro™.

The InnoventPro is slated to be on display for the first time in ExOne’s booth in Hall 12.0, Booth D69 at Formnext 2021 from Nov. 16-19 in Frankfurt, Germany. The machine is available for early-access machine customers in the first half of 2022, with broad availability to follow.

The InnoventPro features Siemens controls, which integrate with the printer drives, motors, sensors, as well as Siemens MindSphere IoT operating system, which powers ExOne’s Scout machine monitoring and analysis app.

Siemens will use the InnoventPro at its Charlotte Advanced Technology Collaboration Hub (CATCH) located in Charlotte, North Carolina to develop materials and processes before taking them to scale on the X1 160Pro.

“We’re very excited to feature the InnoventPro in our Technology Collaboration Hub, and we look forward to demonstrating how to integrate advanced additive manufacturing systems such as the InnoventPro into our end-to-end Digital Thread,” said Tim Bell, Head of Additive Manufacturing, Siemens Industry, Inc. The CATCH facility will leverage Siemens advanced hardware automation and software tools to continue the industrialization of additive manufacturing.

“ExOne is proud to continue offering Siemens technologies in our production-ready metal binder jetting systems, and we’re delighted that Siemens has purchased our new InnoventPro for its own manufacturing use,” said John Hartner, ExOne’s CEO. “Siemens technology continues to deliver important integration value to our production customers, and we’re confident our printer will deliver important manufacturing value to their operations as well.”

InnoventPro Feature Highlights

The affordable new InnoventPro is an all-new package built from the ground up that gives binder jetting customers the most advanced entry-level system on the market in a 3-liter build area of 125 x 220 x 100 mm. Features include:

- Triple ACT advanced compaction technology for precision dispensing, spreading, and compacting of ultra-fine MIM powders, delivering the industry-leading density, accuracy and repeatability that was proven on the Innovent+

- Now packaged with the same faster, smarter, recirculating printhead modules that come standard on ExOne production printers, enabling easy scalability to larger models

- The new printhead will be capable of speeds topping 700 cc/hour on the InnoventPro and printing a new class of patented NanoFuse™ binders embedded with nanoparticles to improve part quality and simplify sintering

- An innovative new comprehensive powder containment system, featuring the ergonomic X1 Powder Grip™ loading system, delivers ease-of-use and improved cleanliness

- Siemens MindSphere powers ExOne’s Scout machine monitoring and analysis app, part of ExOne’s strategy to surround its printers with a complete digital workflow. Scout is available today in the Apple App Store and on Google Play for use with ExOne production sand and metal 3D printers

The InnoventPro was designed by ExOne’s experienced binder jet engineering team based in Pittsburgh, Pennsylvania, and Gersthofen, Germany, with final manufacturing and assembly done in the United States.

Learn more about the InnoventPro at exone.com/innoventpro.

About ExOne

ExOne (Nasdaq: XONE) is the pioneer and global leader in binder jet 3D printing technology. Since 1995, we’ve been on a mission to deliver powerful 3D printers that solve the toughest problems and enable world-changing innovations. Our 3D printing systems quickly transform powder materials — including metals, ceramics, composites and sand — into precision parts, metalcasting molds and cores, and innovative tooling solutions. Industrial customers use our technology to save time and money, reduce waste, improve their manufacturing flexibility, and deliver designs and products that were once impossible. As home to the world’s leading team of binder jetting experts, ExOne also provides specialized 3D printing services, including on-demand production of mission-critical parts, as well as engineering and design consulting. Learn more about ExOne at www.exone.com or on Twitter at @ExOneCo. We invite you to join with us to #MakeMetalGreen™.

About Siemens Digital Industries

Siemens Digital Industries (DI) is an innovation leader in automation and digitalization. Closely collaborating with partners and customers, DI drives the digital transformation in the process and discrete industries. With its Digital Enterprise portfolio, DI provides companies of all sizes with an end-to-end set of products, solutions and services to integrate and digitalize the entire value chain. Optimized for the specific needs of each industry, DI’s unique portfolio supports customers to achieve greater productivity and flexibility. DI is constantly adding innovations to its portfolio to integrate cutting-edge future technologies. Siemens Digital Industries has its global headquarters in Nuremberg, Germany, and has around 75,000 employees internationally.

View source version on businesswire.com: https://www.businesswire.com/news/home/20211109005404/en/

Sarah Webster

Chief Marketing Officer

724.516.2336

sarah.webster@exone.com