- Home

- Binder Jetting Resources

- Blog

ExOne Metal Binder Jet Now Available in Siemens Advanta AM Factory Planning Toolbox

ExOne Metal Binder Jet Now Available in Siemens Advanta AM Factory Planning Toolbox

ExOne Metal Binder Jet Now Available in Siemens Advanta AM Factory Planning Toolbox

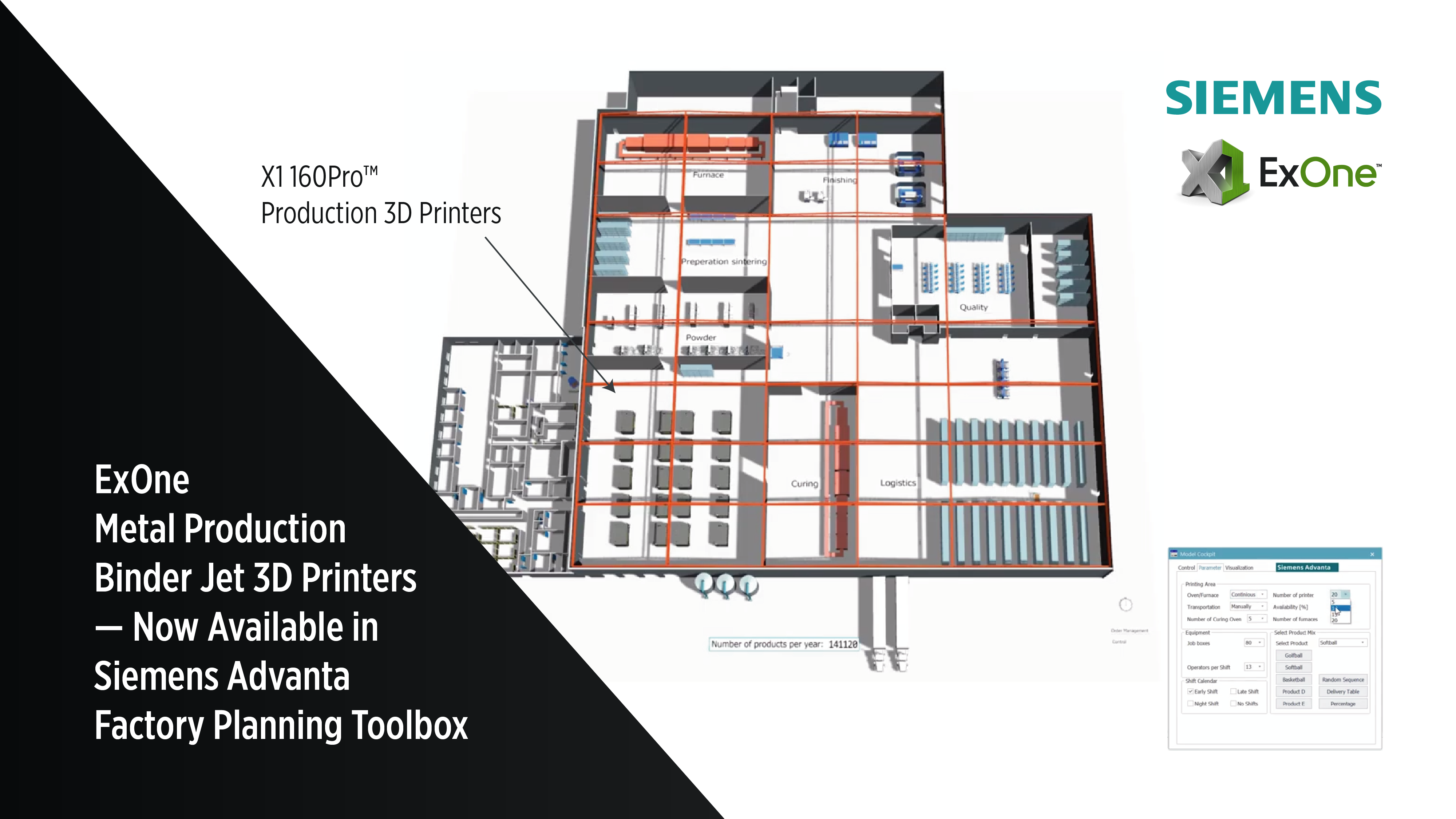

Manufacturers can now plan and optimize their AM processes and resources before implementation fostered by visualization of high-volume 3D printing in action

Siemens Advanta, Siemens' strategical business unit focusing on IoT and digital transformation, has now incorporated metal binder jetting technology from The ExOne Company into its AM Factory Planning library - the first metal binder jetting system to be included in the software suite.

In particular, the Factory Planning library now incorporates the X1 160Pro™, which is ExOne largest metal binder jetting system, into the simulation software to virtually simulate and optimize the full binder jetting process, which requires 3D printing, oven curing, depowdering, and sintering before final finishing and recycling of material with powder conditioning.

Using Siemens Tecnomatix Plant Simulation, Siemens Advanta can assist manufacturers to optimize material flow, resource utilization and logistics for all levels of plant planning from global production facilities, through local plants, to specific lines.

For binder jetting, the software can help determine how many pieces of equipment are needed to efficiently execute on specific production levels for specific parts or sets of parts, and to explore task-time scenarios for different types of parts and equipment long before any real system is installed.

Further, extensive analysis tools, statistics and charts let users evaluate different manufacturing scenarios and make fast, reliable decisions in the early stages of production planning.

We're proud to have ExOne binder jetting technology incorporated into this useful Siemens tool to help our customers prove out their manufacturing resources and concepts prior to the purchase of full work cells,” said Rick Lucas, ExOne Chief Technology Officer and VP, New Markets. As ExOne technology continues to make inroads toward high-volume production, we believe this simulation software will be of increasing value to our customers. It's also helped the ExOne team see our vision for future manufacturing in action, as well as identify opportunities for advancing the technology.

ExOne is looking to streamline the entire binder jetting process with automation, software and remote monitoring. The X1 160Pro™ is the pinnacle of ExOne's production metal binder jetting family and comes equipped with Siemens Automation Technology, which enables a seamless integration. As all of ExOnes current production printers, including the 25Pro®, are equipped with Siemens MindSphere, which powers the ExOne Scout app for remote system monitoring and analysis.

WATCH THE DEMO

Among the inputs that can be selected for factory planning simulation with the ExOne 160Pro:

Number of 3D Printers

Type of Furnace

Manual or AGV Transport of Powder Boxes

Layout Changes

Capacity Utilization Requirements

Number of Curing Ovens

Number of Operators or Shifts

I'm Interested in Learning More

.PNG?ext=.png)