- Home

- Binder Jetting Resources

- Blog

ExOne Updates Vision for Production Metal 3D Printing With New X1D1 Automated Guided Vehicle

ExOne Updates Vision for Production Metal 3D Printing With New X1D1 Automated Guided Vehicle

ExOne Updates Vision for Production Metal 3D Printing With New X1D1 Automated Guided Vehicle

The AGV can support multiple 3D printers and processes efficiently, reducing the total footprint of the system and simplifying timed movements between processes.

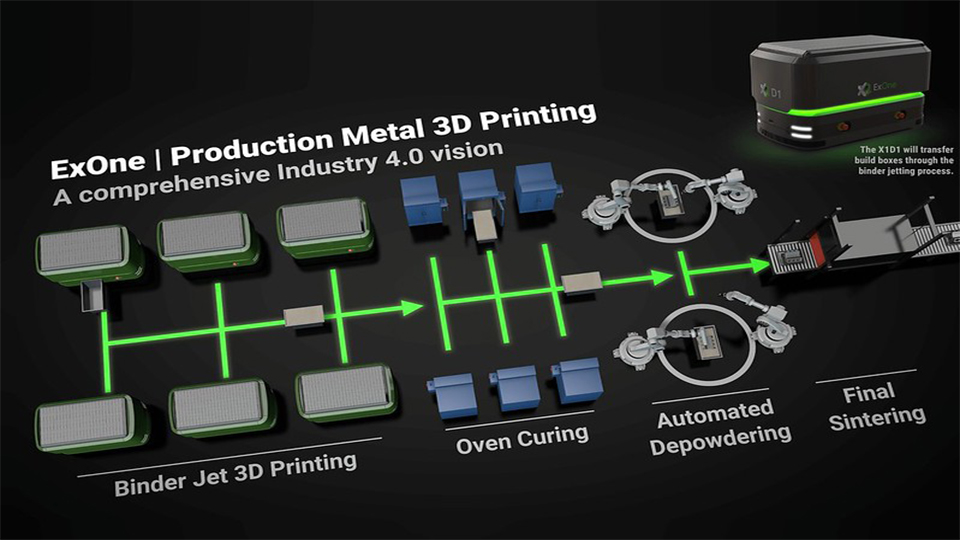

NORTH HUNTINGDON, Pa.--(BUSINESS WIRE)--The ExOne Company (Nasdaq: XONE), the global leader in industrial sand and metal 3D printers using binder jetting technology, today debuted a concept rendering of the new X1D1 automated guided vehicle, which will enable efficient transport of 3D printed build boxes through the binder jetting process.

The X1 160Pro™ extra-large production metal 3D printer, which begins shipping to customers later this year, will be offered with either a standard conveyance system or the new X1D1 to provide manufacturers with greater layout flexibility and efficiency. The AGV can support multiple 3D printers and processes efficiently, reducing the total footprint of the system and simplifying timed movements between processes.

“As part of our discussion with manufacturers, we’ve updated our vision for the production binder jetting work cell, developing an option that  provides high-volume manufacturers with more intelligent flexibility and better use of factory space,” said John Hartner, ExOne CEO.

provides high-volume manufacturers with more intelligent flexibility and better use of factory space,” said John Hartner, ExOne CEO.

The X1 160Pro will also be offered with ExOne Scout, a previously-announced Industry 4.0 app that provides real-time machine monitoring and analysis of production 3D printers on a wide range of digital devices, including smart phones and watches. Scout is enabled by Siemens MindSphere, an Internet-of-Things operating system with multilayered security.

“While ExOne’s production metal 3D printers will remain the centerpiece of our digital manufacturing vision, we’re looking to streamline the entire sequence of processes around our systems with automation, software and remote monitoring and controls,” Hartner said. “ExOne Scout and the X1D1 are moving us toward a complete digital manufacturing package that is smart and efficient.”

A Complete Binder Jetting Vision

The X1 160Pro is ExOne’s 10th metal 3D printer and the company’s largest system of its kind, capable of 3D printing a wide range of metal and ceramic materials into high-density precision parts with exclusive binder jetting technology. With print speeds topping 10,000 cc/hour, depending on print material, the X1 160Pro is designed to deliver the best quality part at production speeds.

Binder jetting is a groundbreaking 3D printing process that uses a digital file to quickly inkjet a binder into a bed of powder particles — metal, sand or ceramic — creating a solid part one layer at a time. When printing metals, the final part must be sintered in order to fuse the particles together into a solid object.

The new X1D1 AGV will lock into place at the front of the 160Pro, and will be able to roll a build box into and out of the machine. With a build volume of 160 liters, a full build box of metal powder will often weigh more than 700 kilograms, or more than 1,500 pounds. After printing, the X1D1 will transport the build box to a curing oven, where the parts are dried, before moving to an automated depowdering and cleaning station, enabled by robot arms and other yet-to-be-announced innovations, before final sintering.

The ExOne Company will offer the X1D1 automated guided vehicle to work alongside the X1 160Pro™ production metal 3D printer. The AGV will enable automated and efficient Industry 4.0 transport of 3D printed build boxes through the binder jetting process.

About ExOne

ExOne is the pioneer and global leader in binder jet 3D printing technology. Since 1995, we’ve been on a mission to deliver powerful 3D printers that solve the toughest problems and enable world-changing innovations. Our 3D printing systems quickly transform powder materials — including metals, ceramics, composites and sand — into precision parts, metalcasting molds and cores, and innovative tooling solutions. Industrial customers use our technology to save time and money, reduce waste, improve their manufacturing flexibility, and deliver designs and products that were once impossible. As home to the world’s leading team of binder jetting experts, ExOne also provides specialized 3D printing services, including on-demand production of mission-critical parts, as well as engineering and design consulting. Learn more about ExOne at www.exone.com or on Twitter at @ExOneCo. We invite you to join with us to #MakeMetalGreen™.

Contacts

Media:

Sarah Webster

Global Marketing Director

724-516-2336

sarah.webster@exone.com

.PNG?ext=.png)