- Home

- Binder Jetting Resources

- Blog

ExOne Launches #MakeMetalGreen Campaign

ExOne Launches #MakeMetalGreen Campaign Encouraging Manufacturers to Re-Examine Production of Metal Parts

ExOne Launches #MakeMetalGreen Campaign Encouraging Manufacturers to Re-Examine Production of Metal Parts

New social campaign to focus on sustainability aspects of binder jet 3D printing technology, including shorter supply chains

- New social campaign to focus on sustainability aspects of binder jet 3D printing technology, including shorter supply chains

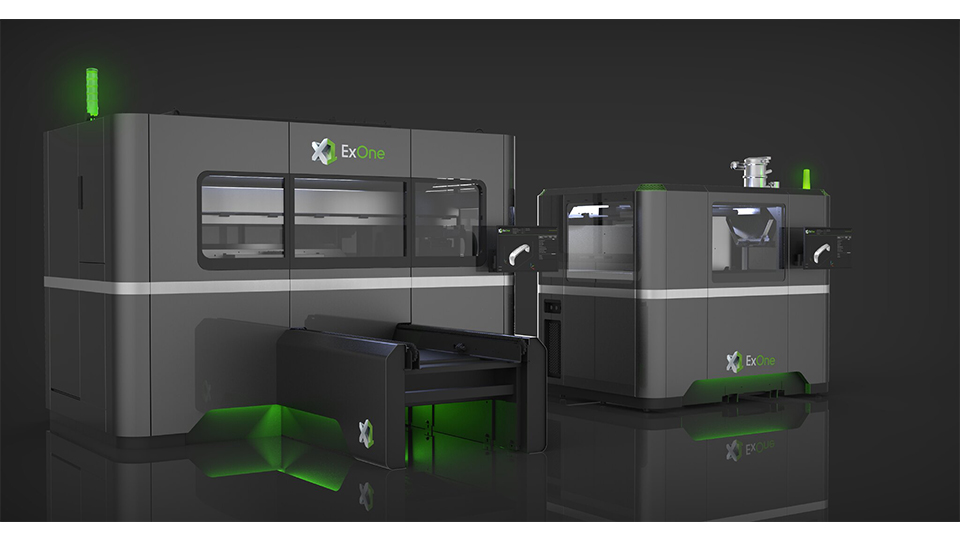

- Updated design unveiled for company’s production metal printers, featuring green LED lighting to highlight the technology’s sustainability benefits

- New virtual reality experience now available to demonstrate a sustainable metal 3D printing factory in action, also to be showcased at IMTS 2020

NORTH HUNTINGDON, PA, May 13, 2020 – The ExOne Company (Nasdaq: XONE), the global leader in industrial sand and metal 3D printers using binder jetting technology, today announced a new #MakeMetalGreen™ social media campaign to educate manufacturers about the sustainability benefits of metal binder jetting technology.

Binder jetting is a method of 3D printing in which an industrial printhead deposits a liquid binder onto a thin layer of powdered particles, layer by layer, until an object is formed. ExOne systems currently 3D print more than 20 metals, ceramics and composite materials. Binder jetting is a sustainable manufacturing technology because it:

- Fabricates metal objects with little to no waste, offering a dramatic improvements over traditional manufacturing methods

- Enables all-new lightweight metal part designs, including those that consolidate many pieces of a product into a single unit, while preserving function and strength

- Produces parts that can make cars, trucks, airplanes and other equipment more fuel-efficient and also dramatically shorten supply chains, consuming far less energy

While other forms of 3D printing can deliver some of these benefits, binder jetting is unique among additive manufacturing processes because it can 3D print parts at high speeds and volumes that make a meaningful difference to long-term sustainability efforts.

“Now is the time for manufacturers to rethink how they manufacture metal parts, and take a new look at how binder jet 3D printing can make metal parts and products more sustainably,” said John Hartner, ExOne CEO. “One important aspect of sustainability is shortening supply chains. Our technology can consolidate several parts into one, eliminating extra manufacturing steps, and also reduce the need for parts to be shipped around the world for final assembly.

“The COVID-19 pandemic has highlighted the importance of de-risking supply chains and moving toward a decentralized supply chain, especially for critical parts. ExOne can work with manufacturers to ensure critical metal parts are prepared for 3D printing in an emergency and to help manufacturers redesign their parts for metal 3D printing in the first place.”

An Updated Green Look, Experience

Since its inception in 1995, ExOne has always been focused on the sustainability features of its core binder jetting technology, as reflected in the company’s green logo. Recently, ExOne also updated the design of the X1 25Pro™ and X1 160Pro™ production metal 3D printers to emphasize the sustainability features of its technology. ExOne’s two newest metal printers feature a charcoal metal body style, a stainless steel silver beltline, rounded corners and green LED lighting.

The new look is also featured in a virtual reality factory experience that ExOne will unveil publicly at the International Manufacturing Technology Show in Chicago Sept. 14-19. ExOne will be located in IMTS booth 433103, on Level 3 of the West Building of McCormick Place.

VR headsets are also being made available today for qualifying companies who wish to explore binder jetting in a life-size model. A sign up form and preview of the VR experience is available at www.exone.com/VR.

The new machine designs, which will serve as the standard for ExOne metal printers going forward, as well as the virtual reality experience, were developed in conjunction with Bally Design, an industrial design consultancy in Pittsburgh, PA that specializes in industrial design, user interface design, digital business models, and virtual reality.

A Full Family of Metal 3D Printers

ExOne currently offers four metal 3D printers that can accommodate applications ranging from R&D and prototyping to various forms of production:

- Innovent+, an entry-level model used globally for research, design and small part production of metal, ceramic and composite materials

- M-Flex, a large 3D printer that produces parts in a wide range of coarse-grain metal, ceramic and composite powders

- X1 25Pro, a large metal 3D printer, currently shipping to customers, that prints high-density metal, ceramic and composite parts for production

- X1 160Pro, an extra-large binder jetting system for 3D printing high-density metal parts for high-volume production. Shipping to customers is slated to begin by year-end

The Innovent+, X1 25Pro and X1 160Pro all feature ExOne’s patented and exclusive Triple ACT system – advanced compaction technology for dispensing, spreading, and compacting ultra-fine MIM powders for high-density, high-quality metal parts. Triple ACT delivers industry-leading density and repeatability across the entire build area in metal binder jetting.

About ExOne

ExOne is the pioneer and global leader in binder jet 3D printing technology. Since 1995, we’ve been on a mission to deliver powerful 3D printers that solve the toughest problems and enable world-changing innovations. Our 3D printing systems quickly transform powder materials — including metals, ceramics, composites and sand — into precision parts, metalcasting molds and cores, and innovative tooling solutions. Industrial customers use our technology to save time and money, reduce waste, improve their manufacturing flexibility, and deliver designs and products that were once impossible. As home to the world’s leading team of binder jetting experts, ExOne also provides specialized 3D printing services, including on-demand production of mission-critical parts, as well as engineering and design consulting. Learn more about ExOne at www.exone.com or on Twitter at @ExOneCo. We invite you to join with us to #MakeMetalGreen™.

About Bally Design, Inc.

Bally Design, located in Pittsburgh, Pennsylvania, is an industrial design and graphical user interface design firm founded in 1976. Bally’s core competency is at the intersection of digital and physical solutions where creativity is needed to complete the digital transformation of industrial processes. Bally Design’s multi-disciplinary approach is based on discovery, learning, and understanding of the needs of a diverse group of stakeholders. Our team of facilitators, market researchers, industrial designers, and graphic designers draw on diverse perspectives to problem-solving to create design solutions that result in successful products and enhance the customer experience.

Contacts

Media:

Sarah Webster

Global Marketing Director

724-516-2336

sarah.webster@exone.com

.PNG?ext=.png)