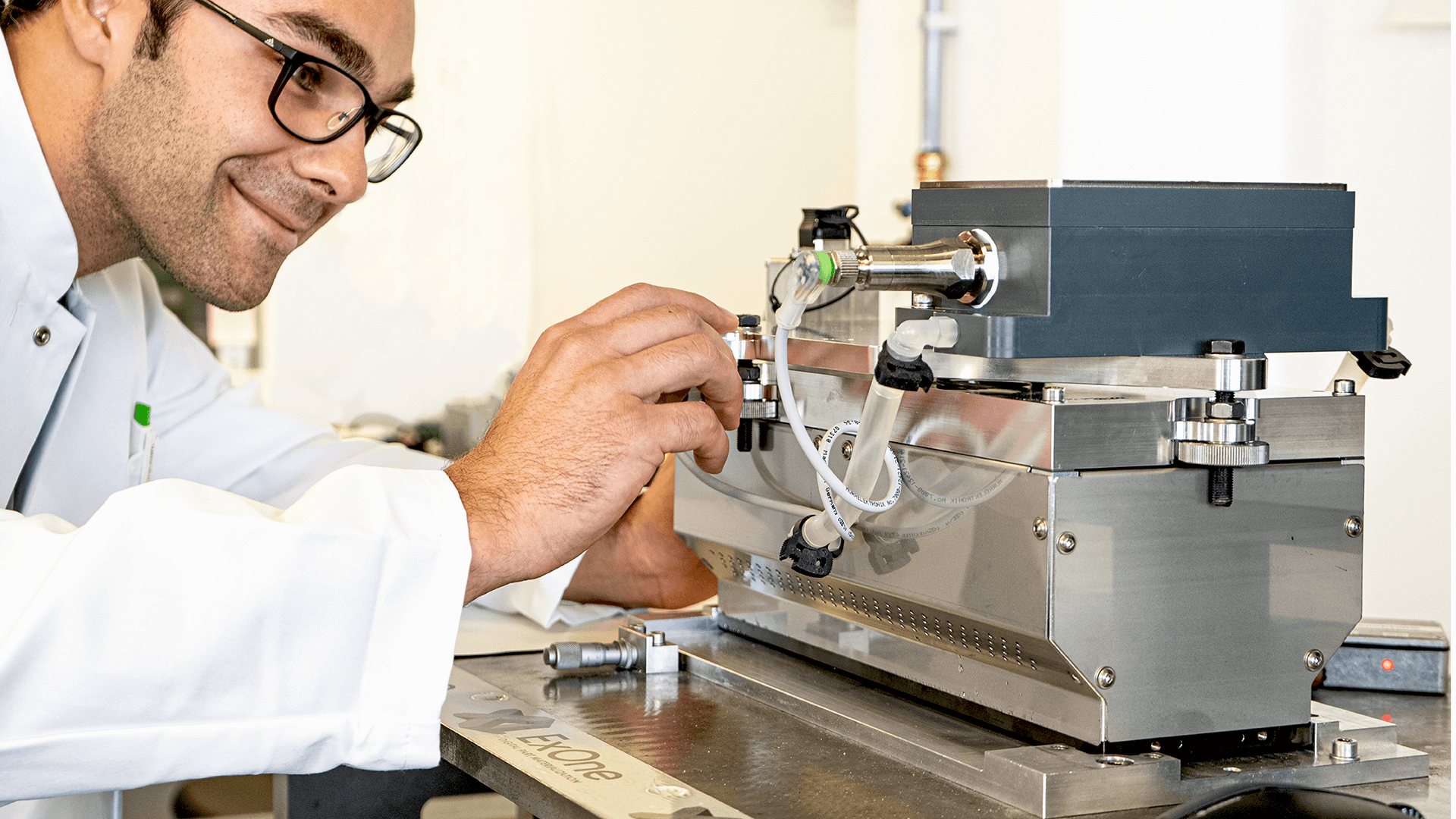

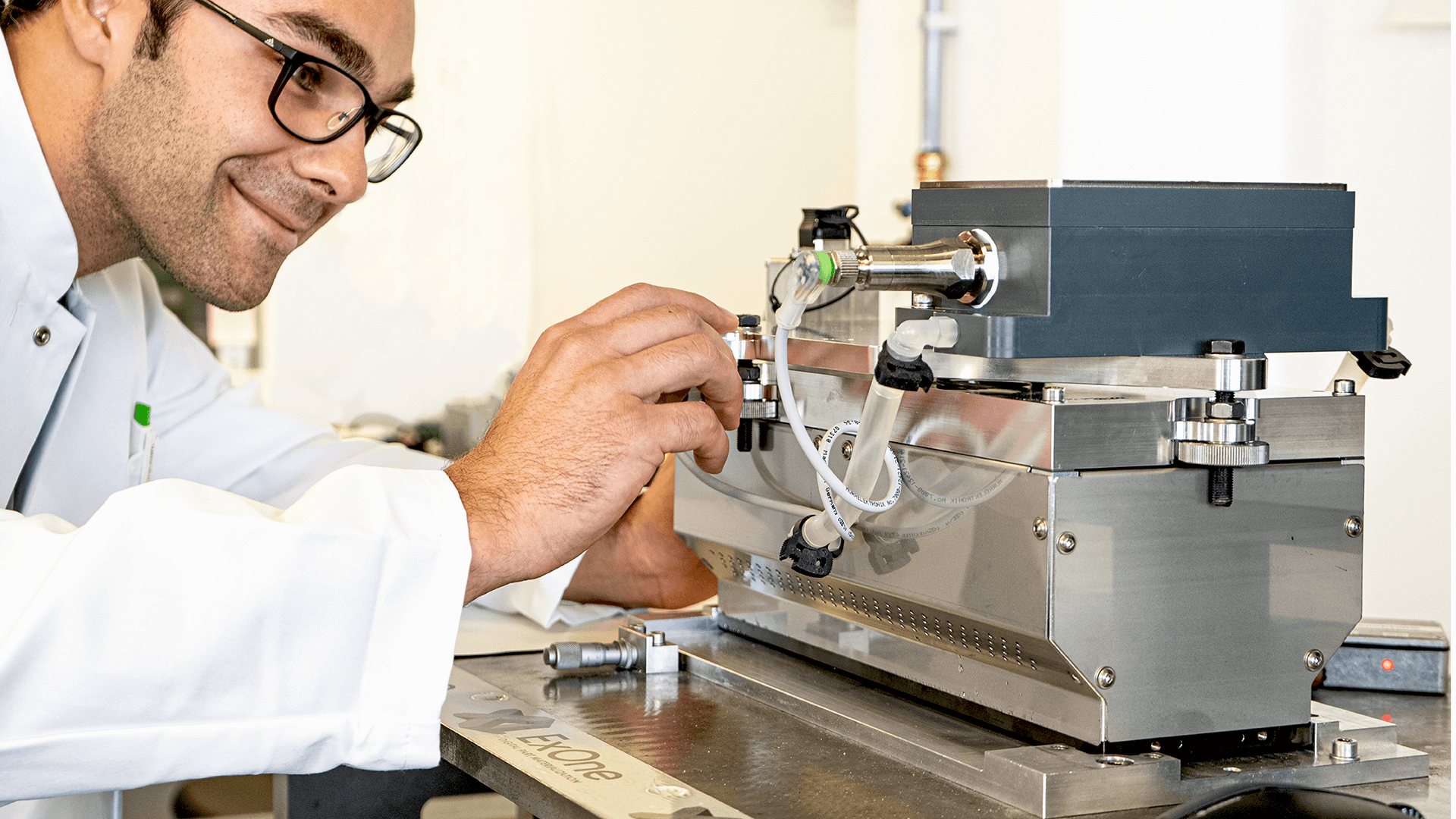

Comprehensive R&D Services for Binder Jet 3D Printing Projects and Programs

Metal, Sand, Ceramic and Composite Parts and Tooling

Comprehensive R&D Services for Binder Jet 3D Printing Projects and Programs

Metal, Sand, Ceramic and Composite Parts and Tooling