- Home

- Binder Jetting Resources

- Blog

Reduce, Reuse, Recycle: Getting Specific About Where 3D Printing Hits the Mark

Reduce, Reuse, Recycle: Getting Specific About Where 3D Printing Hits the Mark

Reduce, Reuse, Recycle: Getting Specific About Where 3D Printing Hits the Mark

How additive manufacturing (AM) delivers on sustainability

ExOne Technical Fellow

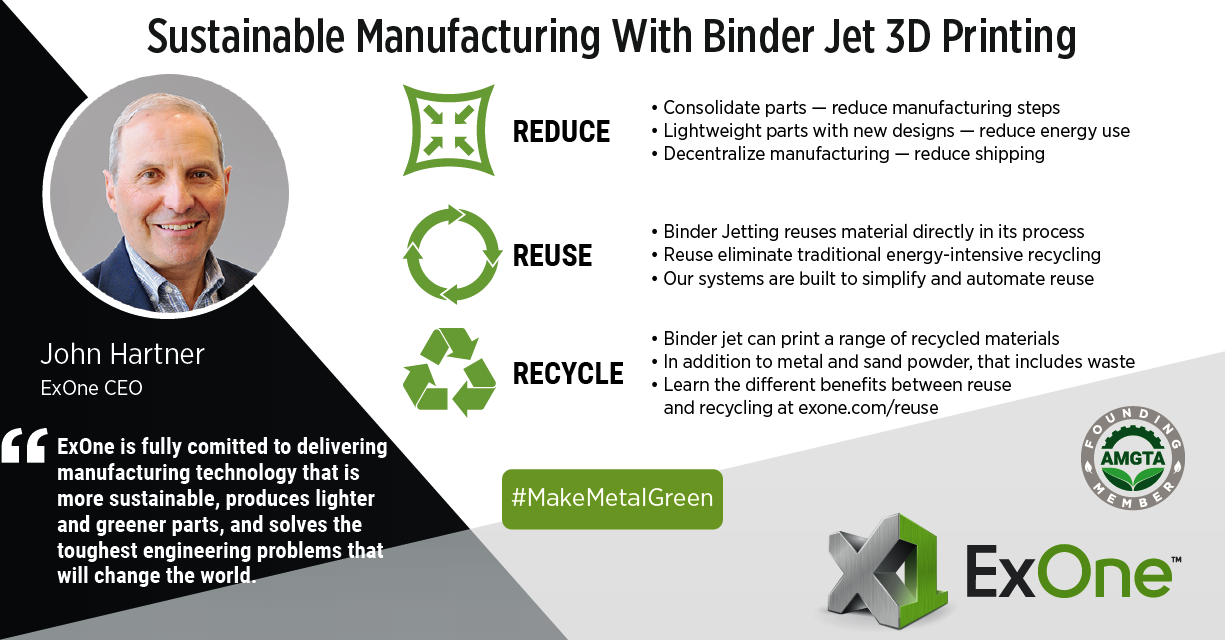

Reduce, Reuse, Recycle. The three Rs of green were first coined sometime in the 1970s. We’ve all heard the terms, but they all deliver different types and levels of benefits in general and especially in 3D printing or AM.

On Earth Day, we thought it would be a good time to review how AM delivers on these benefits, and important changes coming from standards-issuing bodies and other organizations such as the Additive Manufacturer Green Trade Association (AMGTA) to clarify and quantify these benefits.

Reduce with AM and Binder Jet

When we use fewer resources from the beginning, we also reduce the need to recycle and reuse. For individuals, it means things such as turning off the lights in unused rooms, taking a shorter shower, or setting the heater to 66˚F.

In manufacturing, this could mean using less material to deliver a given geometry, using less energy to create a part, or using less labor for the full execution of a manufacturing process. Shortening the distance from supplier to producer or producer to customer with localized or decentralized manufacturing strategies also counts.

With modern engineering tools and computer aided manufacturing, product development cycles can consume less time and money than physical prototyping. We can use more digital twins, digital analysis, and digital simulation. We can consume less real resources and more virtual ones.

One of the most meaningful methods of reducing with additive is to consolidate several parts into one, reducing manufacturing and assembly steps, or lightweighting a part with radically optimized topology that enables a new geometry that delivers the same or improved functional benefits with less weight. It’s common in parts redesigned for binder jet, for example, to deliver weight savings of 30-50%. What’s more, you can take a traditional stainless steel part, optimize the design, and print it in a new material such as aluminum that amplifies the benefits even more. This is one of the reasons why ExOne’s recent qualification of 6061 aluminum with Ford Motor Co. is so important for the future.

When it comes to the sustainability benefits that come from this “reduce” category, almost all forms of additive manufacturing have you covered. But some specific AM processes offer enhanced benefits. For example, binder jet can print high volumes of parts with ease, allowing more meaningful benefits across more parts.

Reuse or Recycle?

When it comes to reuse or recycling, we haven’t been as good at distinguishing between the two. But these are two very different Rs in sustainability. Indeed, even the icons for the two Rs are very similar, with reuse showing an effortless circle of arrows and recycling showing a triangle of arrows to demonstrate a bit of extra effort.

At the end of the day, recycling is also sort of a consolation approach: if we can’t stop being more wasteful to begin with, let’s at least recycle.

But the truth is recycling is very resource-intensive to begin with, consuming a lot of energy and time. It’s spent sorting, cleaning, transporting, refining, and reforming all sort of items in recycling. If reduced or reused in the first place, we could greatly reduce this consumption as well.

Consider the normal, everyday scrap generated in a CNC manufacturing shop. It’s tempting to think that all of those chips are sent right back to the refiner and returned as new steel or aluminum to cut. It’s far from being that simple. The chips are fouled with cutting fluids and tramp oils and they need to be cleaned and dried. Chips of different metals need to stay sorted and warehoused between pickups. And while good plant hygiene can alleviate some of these difficulties, it takes ongoing investments. Which means that more swarf makes it into landfills than you might expect. It’s a complicated subject you can learn more about here: Scrap Metal Determination and Disposal - NES (nesglobal.net)

The High-Efficiency of Reuse

But what if we could reuse more material without recycling? What if we could reuse material directly in a manufacturing process many, many times before it’s recycled?

A 2020 research paper in The Minerals, Metals & Material Society, “Metal Powder Recyclability in Binder Jet Additive Manufacturing,” concluded one could recycle powder up to 16 times in the binder jetting process – delivering an overall efficiency of material consumption of up to 96%. If you dig into the article a bit deeper, you’ll find it’s really more about reusing material directly in the process rather than recycling.

This brings me to an interesting conversation that recently happened in the SAE workgroup writing standards for metal AM. There’s a committee writing the standard AMS 7031 – Process Requirements for Recovery and Recycling of Metal Powder Feedstock for Use in Additive Manufacturing of Aerospace Parts.

And they’re changing the title to replace Recycling with Reuse.

It’s true some processes generate spatter that can’t be reused, or even in binder jetting some stray satellites can form agglomerates that get sieved out. But in many powder-based AM processes, that’s not what happens to the bulk of any given powder batch. For almost every powder, in every process, powder can be circulated through the system several times before it must be recycled, as demonstrated in the research paper cited above.

That’s where the conversation gets interesting at the SAE. The committee came to a consensus that we need to change the way we write these standards moving forward. We don’t recycle powder, we reuse it, and that will be the term moving forward. That’s a big difference for such a small word. It’s another compelling reason to switch to AM, and how the true green benefits might be more than you think at first blush. Especially if you’re picturing “True Recycling” every time you hear about depowdering and reconditioning your powder.

Powder reuse is an activity that happens on-site, as a natural part of the technology. At ExOne, we’re designing systems with provisions for maintaining consistent levels of humidity, blending of virgin and recovered powder, and establishing a consistent and stable flow of powdered materials into your printer. It’s been found in binder jetting that this mixture results in a more consistent process.

But what we really need to do in all of additive is a comprehensive value stream map, and that’s the type of scholarly work being started now by AMGTA. ExOne is proud to be a founding member of the organization, and you can read their work here: Resources - AMGTA, where you'll find the most comprehensive study done yet, State of Knowledge on the Environmental Impacts of Metal Additive Manufacturing. In it, they explain the lack of research available, and the difficulty in comparing the data that does exits. You can learn more about the value stream mapping process from the EPA here: E3 Value Stream Mapping How-to Guide | E3: Economy - Energy - Environment | US EPA

All of this is a long way to say that binder jetting’s sustainability benefits have great potential. The technology lets you use less material to start with, innovate more sustainable products, reuse more of the material you have, and avoid resource-intensive recycling as much as possible.