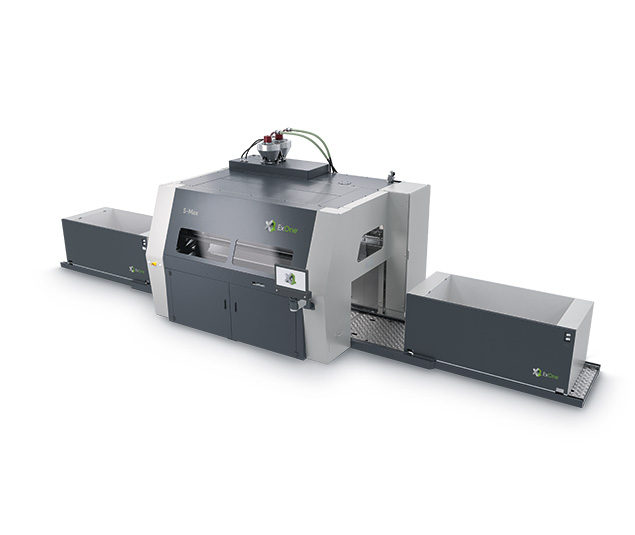

S-Max®

The S-Max® offers a robust and reliable solution for all cold hardening binder systems. It is suitable for almost all casting materials. Large and complex cores and molds can be realized even more quickly and reliably. With a larger building platform and double job box, the S-Max produces any prototype requirement and whole series with efficiency and performance.

System Benefits

- Automated industrial printhead for all cold hardening binder systems (Furan and CHP)

- Large build platform suitable for all prototype requirements as well as serial production

- High productivity and reliability for fast and flexible batch production of sand cores and molds

- Optional second job box on motorized conveyor for continuous 24/7 production

- Desanding station options help cut bulk depowdering times in half

Specifications *

Compare Systems

Binder Systems

Furan | CHP

Build Box

1,800 × 1,000 × 700 mm (70.9 × 39.4 × 27.6 in) (L × W × H)

Build Volume

1,260 l (44 ft³)

Maximum Build Rate

Up to 125 l/h

External Dimensions

110.4 × 3.5 × 2.9 m (34.1 × 11.5 × 9.5 ft) (L × W × H)

Layer Height

0.2 to 0.5 mm (200 to 500 μm)

*Specifications are subject to change without notice. Some data may be dependent on size and characteristics of powder being processed.

Compare Systems

See Specifications

.PNG?ext=.png)