Speed Mold Co Ltd

Speed Mold Co Ltd

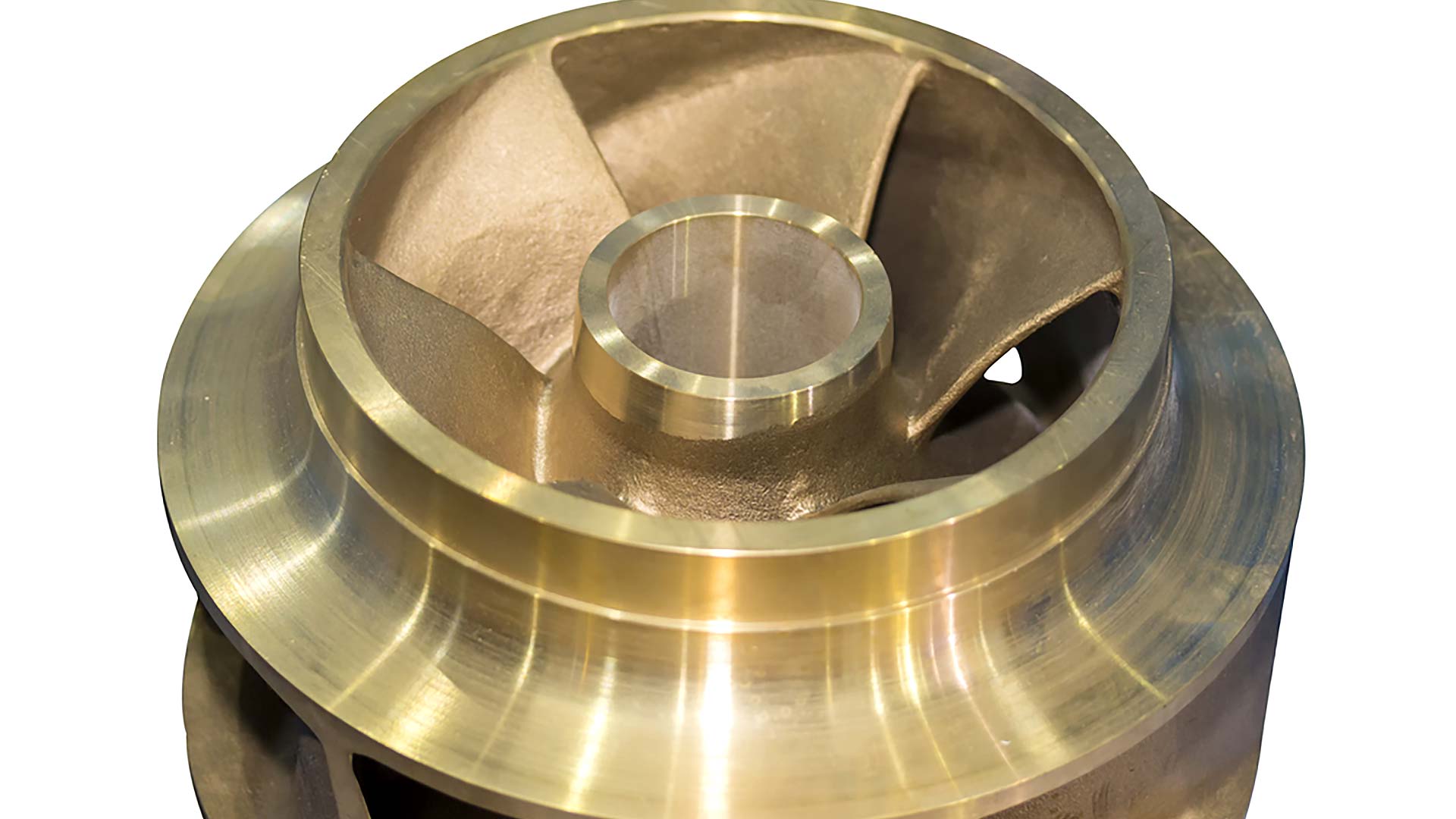

Significantly faster production time, reduction in costs and the ability to ensure quality and accuracy when providing castings.

Documentation

Download Speed 3D Mold Company

Reduced Lead Time and Cost While Ensuring High Accuracy and Quality

.PNG?ext=.png)