- Home

- Binder Jetting Resources

- Blog

Digital Casting Workflows

Streamlining Casting Workflows with Sand 3D Printing

Streamlining Casting Workflows with Sand 3D Printing

Discover how sand 3D printing simplifies casting workflows - cutting lead times and improving labor efficiency in foundry operations.

From design to pour: sand 3D printing in casting workflows is redefining the way foundries operate

In today’s fast-paced manufacturing environment, casting workflows need to evolve. Foundries either innovate and update their workflows or risk becoming obsolete in an increasingly competitive landscape. Traditional casting methods, reliant on hard tooling that demands skilled labor and long lead times, are being transformed by digital innovation. At the heart of this shift is sand 3D printing for casting workflows, using binder jetting technology to boost efficiency, quality, and profitability.

Design faster, iterate smarter

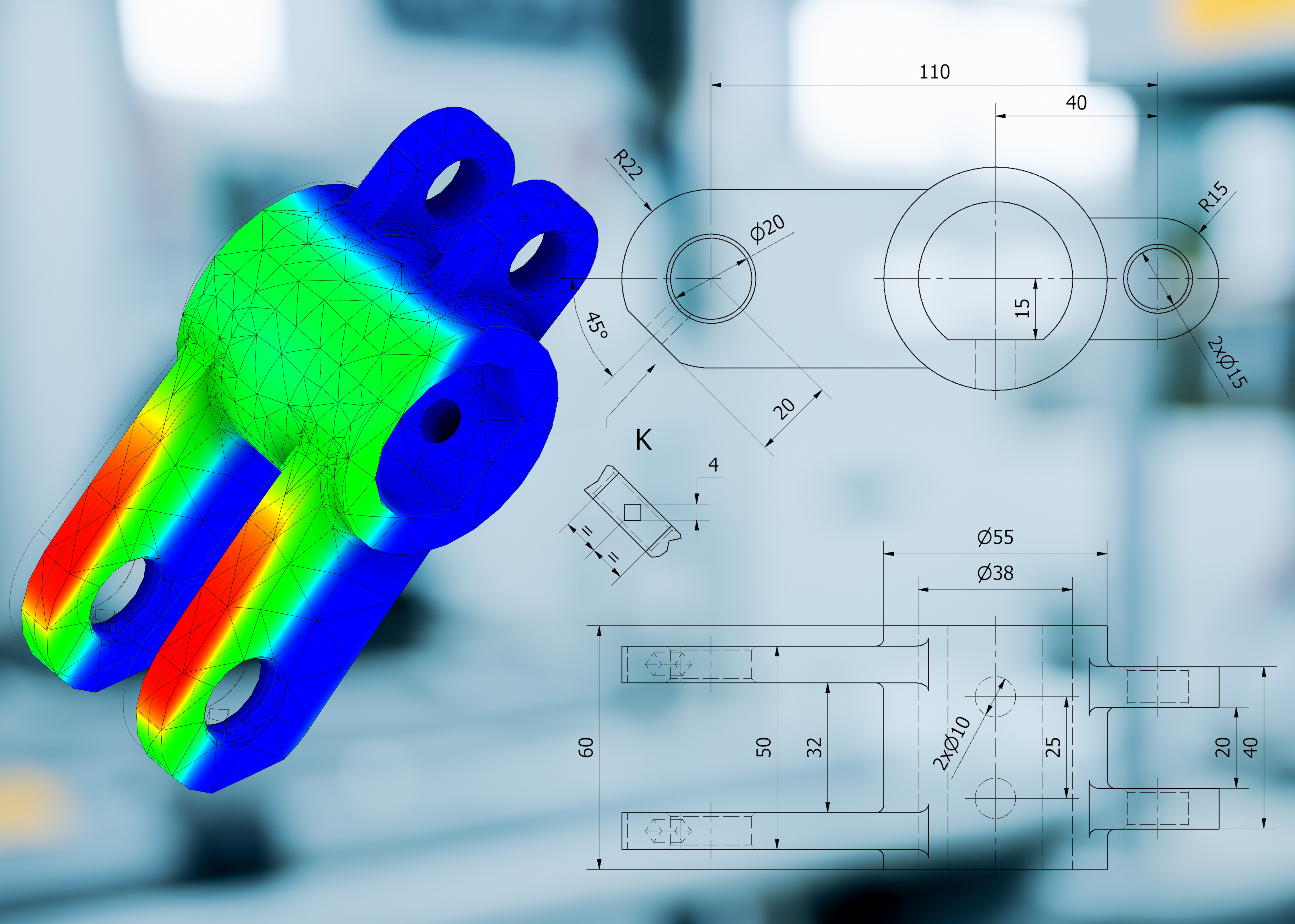

Using CAD-based tools and simulation software, engineers can now design complex molds and cores with unprecedented freedom. These digital files are 3D printed on demand, eliminating the need for physical patterns and tooling. Aside from storage savings, that means design changes happen with a click rather than through labor-intensive manual rework or a complete tool overhaul. Digitally-driven binder jet additive manufacturing enables foundries to rapidly respond to customer requests for modifications and optimize designs for performance, weight reduction, and material efficiency before any physical production begins.

Directly print molds and cores

Once designs are finalized, ExOne's binder jetting technology brings them to life with remarkable precision and speed. Printing sand layer-by-layer according to digital specifications creates tooling without patterns or core boxes. This direct-to-casting approach is a key strength of sand 3D printing for casting workflows. By reducing core assembly and setup time, binder jetting enables faster turnarounds, even on complex geometries that would be costly or impossible to produce with traditional tooling methods.

Reduce errors and scrap

The ability to consolidate multiple cores into single, intricate pieces not only streamlines production, but the elimination of manual core assembly significantly reduces human errors in the casting workflow. Digital simulations performed before physical production begins allow foundries to catch and address potential issues earlier in the process, cutting down on material waste, rework, and costly defects.

Accelerate production cycles

From rapid prototyping to full-scale production, digital casting workflows with sand 3D printing dramatically shrink timelines. What used to take weeks – including design revisions, pattern creation, and core assembly - can now be accomplished in days or even hours. This acceleration enables foundries to meet tight deadlines, reduce inventory costs, and capture new business opportunities that would be impossible with conventional methods.

Optimize efficiency amid labor shortages

Finding labor is an ongoing challenge for foundries. By reducing reliance on highly manual pattern-making and skilled core assembly, digital workflows lighten the load on limited staff. Production automation built around sand 3D printers in casting workflows empowers a leaner, more agile workforce to do more with less - improving throughput without compromising quality. Foundries can redeploy skilled workers to higher-value tasks while the printers handle mold and core production.

A smarter future: embracing the full potential of sand 3D printing for casting workflows

ExOne is the leading partner for digital foundry transformations with cutting-edge sand 3D printing solutions to improve casting workflows. Our sand 3D printing systems and integration services enable manufacturers across industries to work smarter, respond faster to market demands, and compete with confidence in a rapidly evolving landscape. By embracing digital workflows, foundries aren't just updating their production methods - they're futureproofing their businesses.

Real Foundries. Real Solutions.

Read stories and see videos of foundries using ExOne binder jetting to solve real world foundry challenges.

SEE Success Stories

.PNG?ext=.png)