Pump Manufacturer

Pump Manufacturer

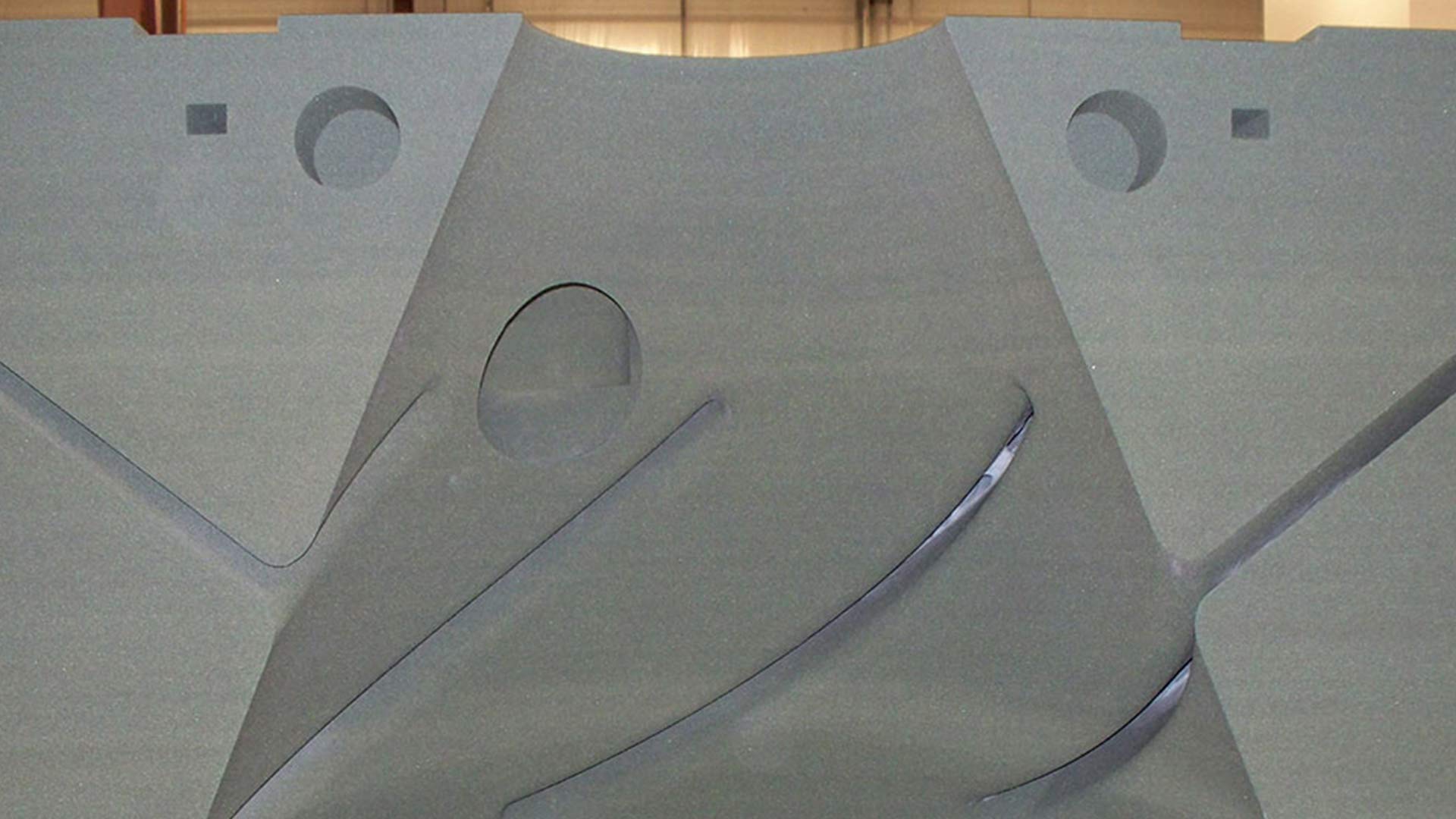

Creating complex prototypes and spare parts quickly and economically to meet tight production schedules.

Documentation

Download Pump Manufacturer Case Study

Save Significant Time and Cost in Spare Part Production

.PNG?ext=.png)