X1 Tooling

Fast. Affordable. Local.

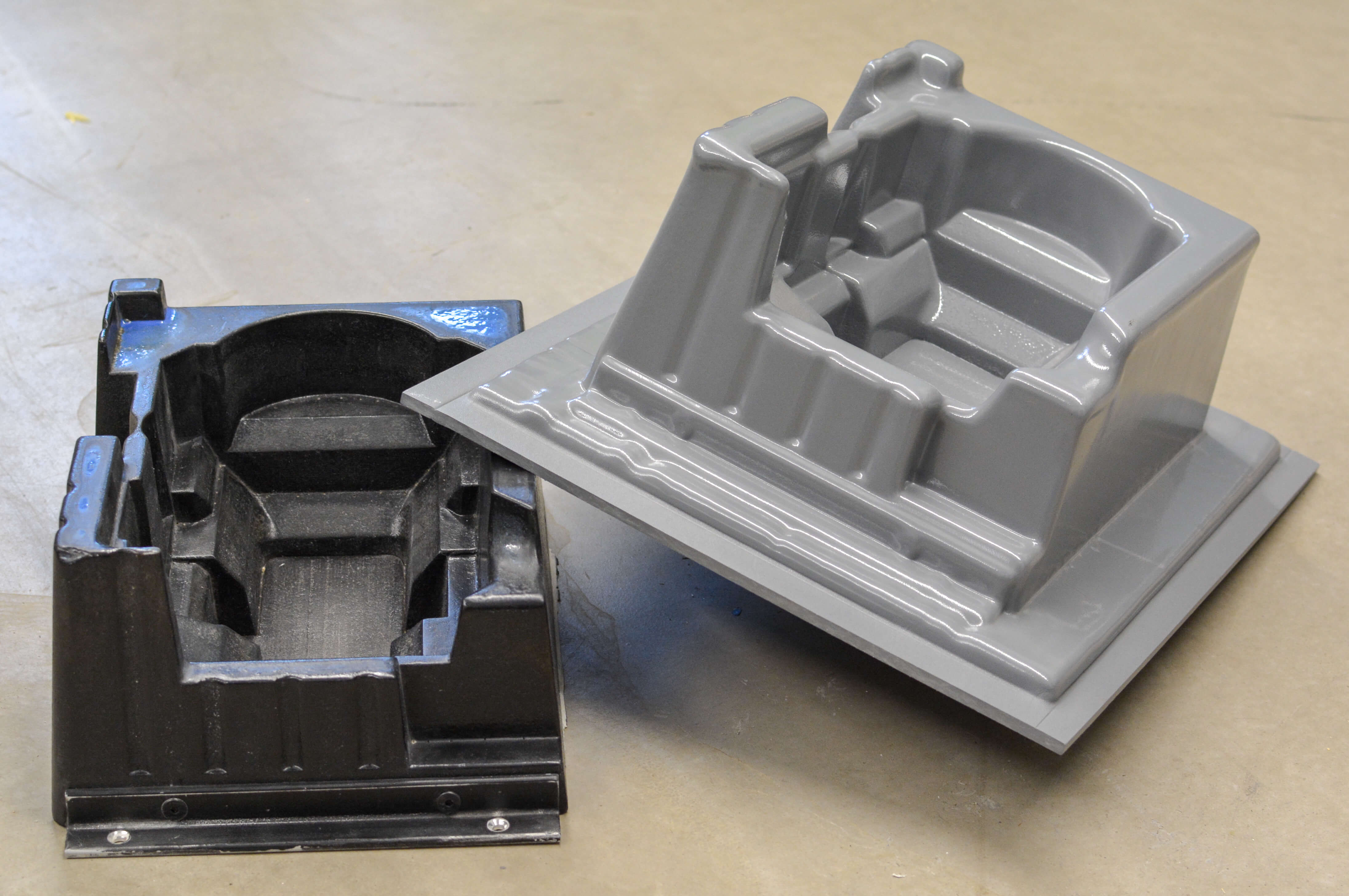

3D printed tools for thermoforming, composite layup, sacrificial tooling, foam molding, and metalcasting. Get complex final parts in days versus weeks and months.

With X1 Tooling, manufacturers now have fast, affordable, and local tooling options for the final production of metal, plastic, and composite designs

KEY FEATURES AND BENEFITS

- Speed: Binder jet 3D printed tools can often be produced in days versus weeks and months

- Cost: Most of our tooling options are cost competitive or offer a cost advantage over traditional tooling options

- Performance: Whether it's reducing cycle time with conformal cooling channels or exploiting generative design concepts, 3D printed tooling can also offer performance benefits in final parts not easily achieved with traditional tooling

ExOne infiltrated sand tooling offers the broadest portfolio of industrial-grade 3D printed tooling available — with new solutions for forming plastics, laying up composites, casting metals, and more. The X1 Tooling portfolio is the direct result of strong customer demand for tooling options that speed up delivery times and bring tooling closer to the point of final production.

Optimize your product development lifecycle, start production while traditional tooling is being made, or eliminate the need for traditional tooling in low- to medium-volume production applications. You can also feel good that our tooling is made with less waste, shipping, and energy.

ExOne’s range of tooling solutions enables on-demand tool production with quick turnarounds and at costs lower than traditional processes. Our range of additive manufacturing options allows you to create unique geometries, iterate quickly, and test functional prototypes to improve your product and get to market faster and cheaper.

Learn More About X1 Tooling

On-Demand webinar for more information on tooling options for the final production of plastic or composite parts.

Watch the webinar