X1 MetalTool

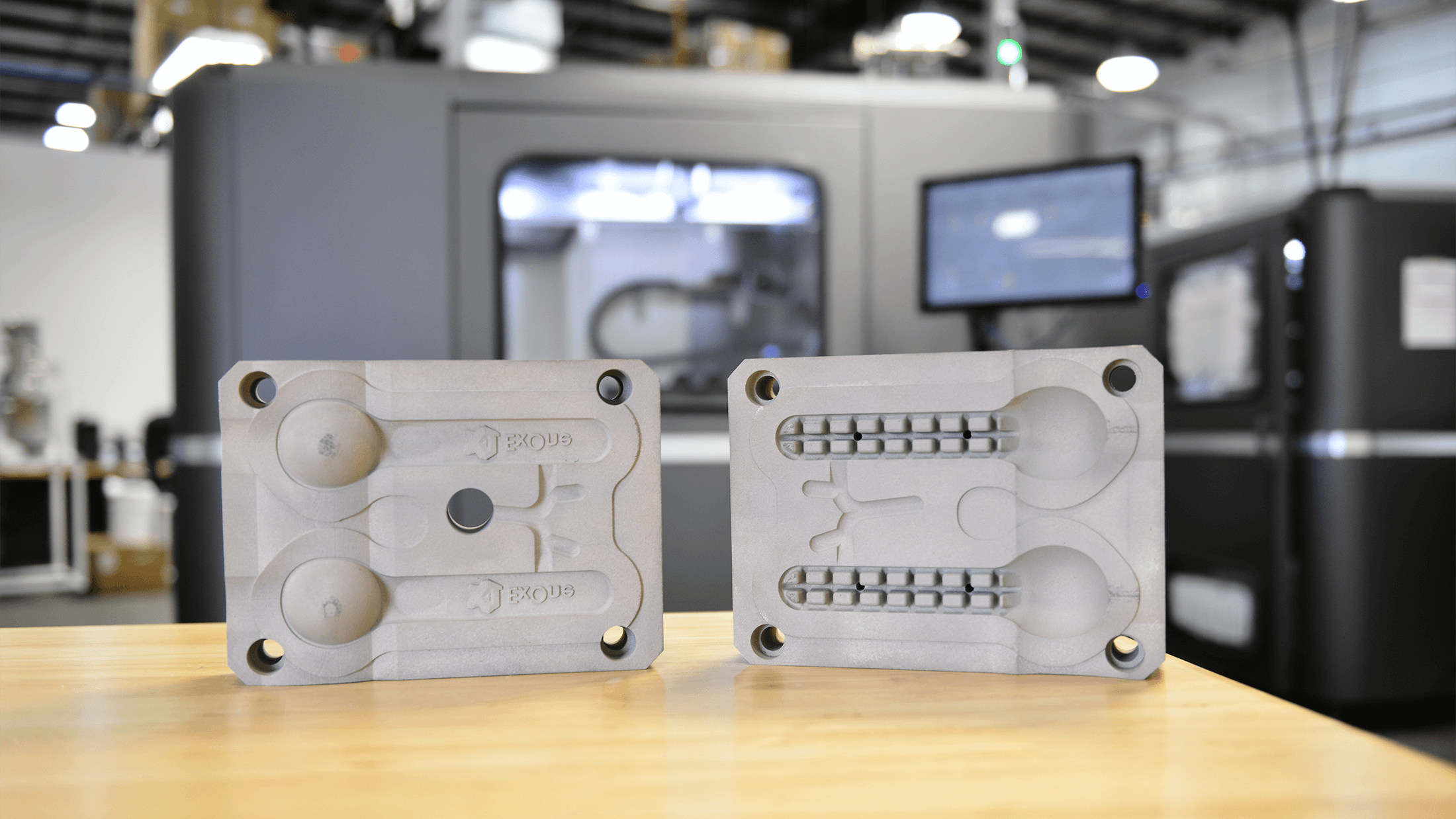

Traditionally machined tools require long leads times and are limited at incorporating advanced geometries, such as conformal cooling channels or organic, lightweight designs.

Learn More About X1 MetalTool

ExOne experts are ready to help you improve tooling turnaround times and performance with 3D printed tools for blow molding, injection molding, and more.

Contact us to get started today

.png?editmode=1&instance=bcb7fd44-436d-4896-bb60-197d2b72d49e)