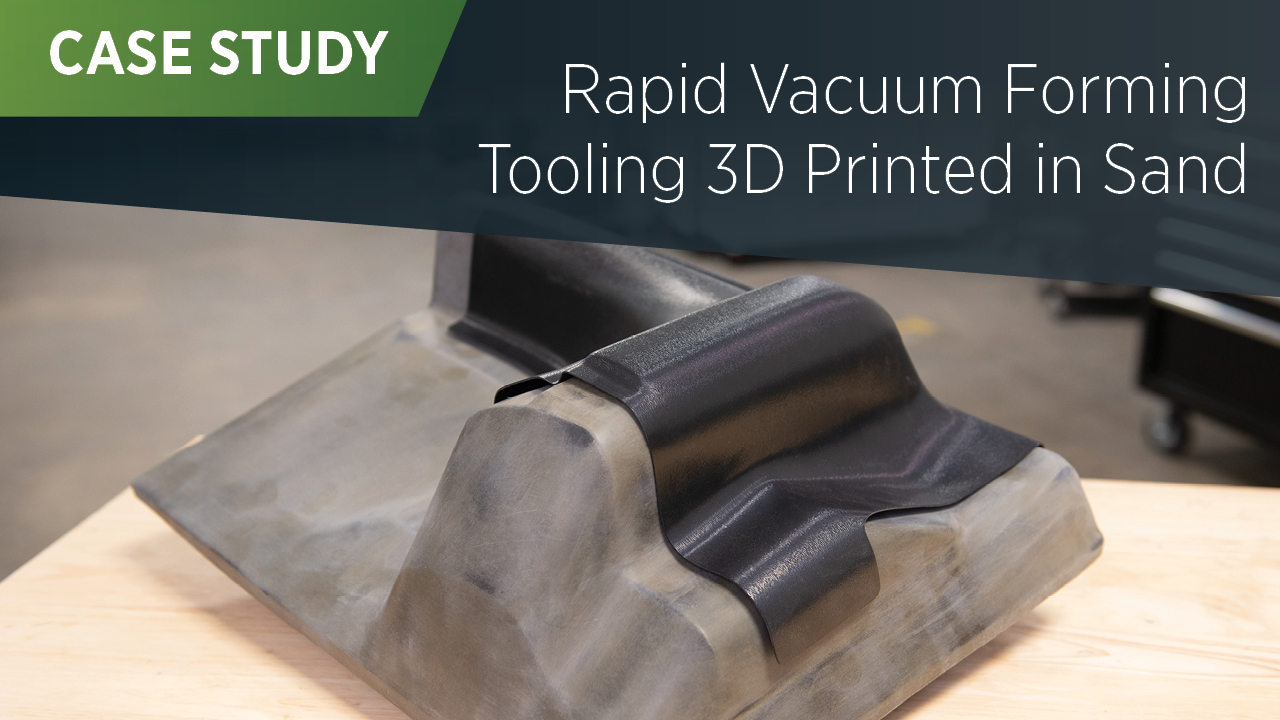

Start Production Faster with 3D Printed Sand Tooling

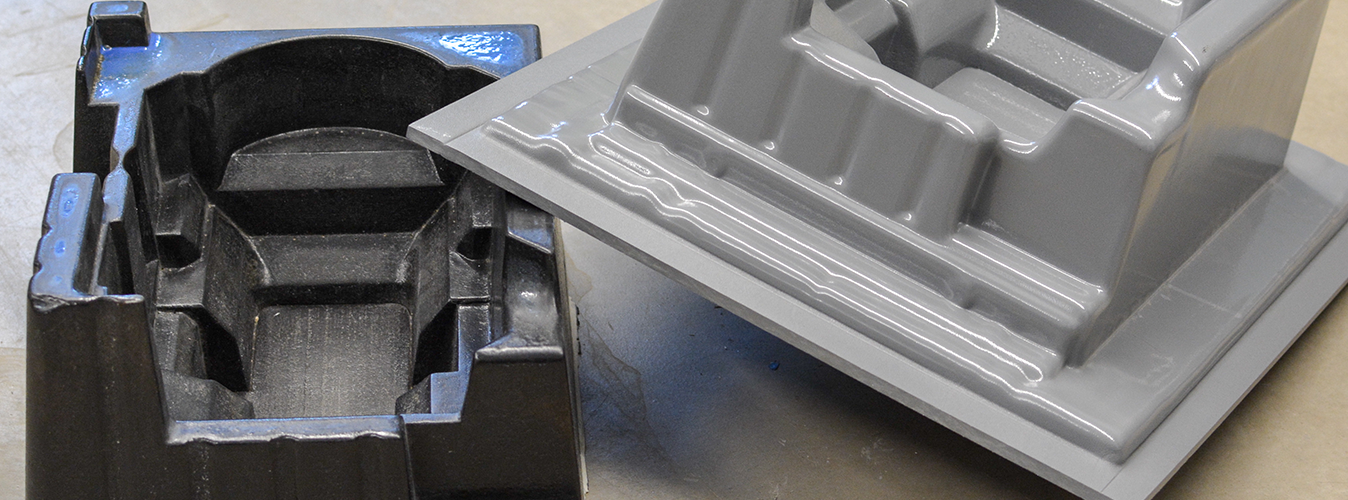

On-demand tooling for thermoforming, vacuum forming, or other compression tooling applications delivers molds more durable than other low-cost options that are able to withstand high temperatures, multiple hits, or even allow for full vacuum to be pulled in the forming process, all without delamination or failure.

Let ExOne 3D Print Your Thermoforming Tools

As a full-service tooling provider, ExOne works with customers every step of the way from tool design guidelines to printing and coating all the way through quality control.

Request a quote for x1 Thermoform

lead times of traditional tools. X1 Thermoform delivers durable, low-cost tooling with fast turnarounds for short-run production or to allow production to begin while you wait for traditional tooling.

lead times of traditional tools. X1 Thermoform delivers durable, low-cost tooling with fast turnarounds for short-run production or to allow production to begin while you wait for traditional tooling.