Standard Alloys

Standard Alloys

From concept to completion in less than 8 weeks to meet critical lead time requirements

Documentation

Download Standard Alloys

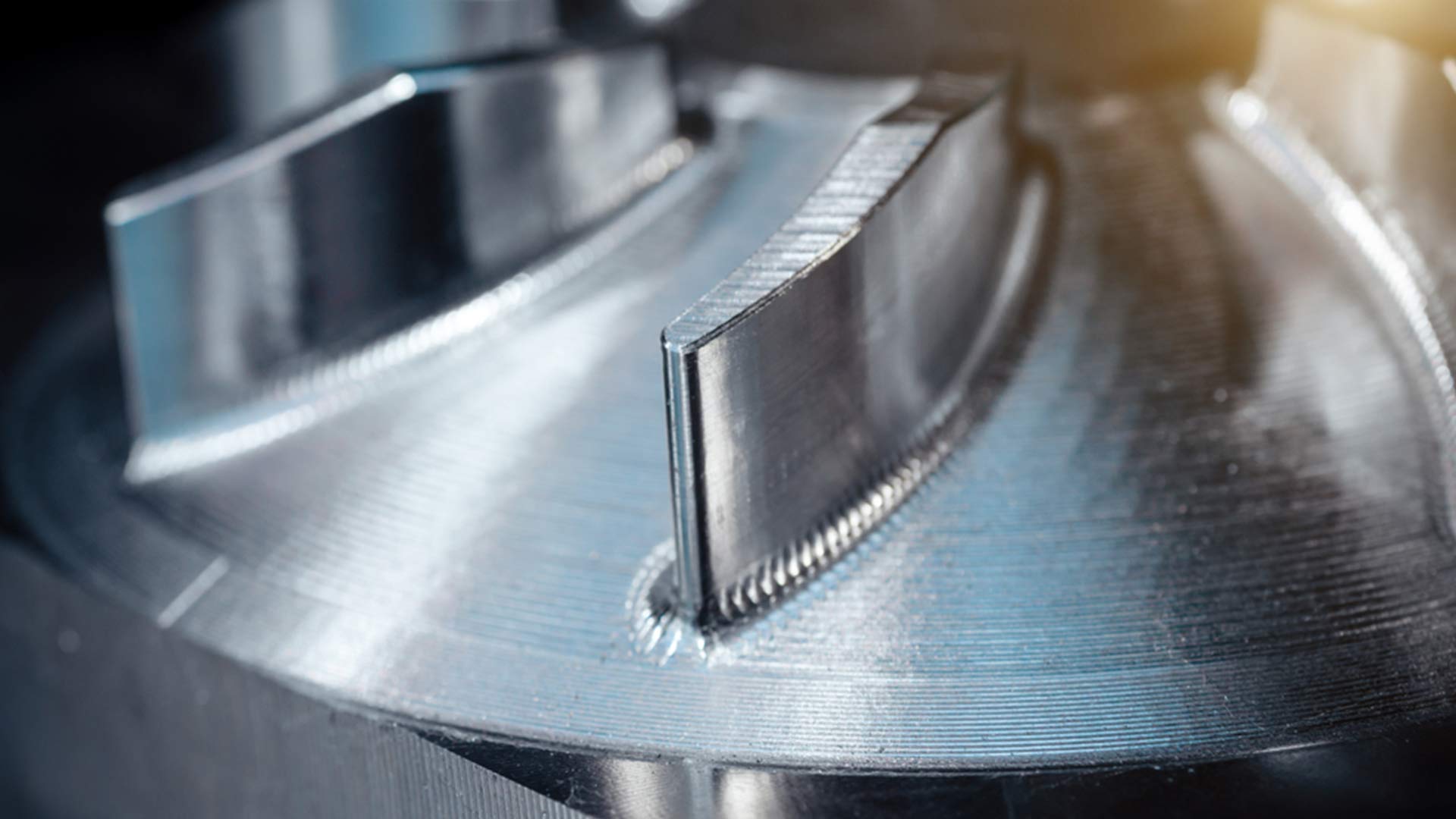

Manufacture a 57 Inch Impeller without a Core Box with ExOne’s Rapid Casting Process

.PNG?ext=.png)