Sand 3D Printers

Sand 3D printers from ExOne® support sandcasting applications across industries, allowing our customers to innovate and provide enhanced design options and solutions for their clients.

The future of industrial development continues to place high demands on foundries and suppliers. Sand 3D printing is at the beginning of its potential.

As the leader in Additive Manufacturing of 3D sand printing, ExOne offers solutions for complex and increasing customer demands that cannot be realized by any other production process. Incorporating ExOne sand mold and core systems helps enhance operations and creates efficiencies for industrial manufacturers moving forward into industry 4.0. Our sand 3D printers can support prototyping, serial production, and parts on demand. Learn more about the versatility afforded by sand 3D printers and how our systems can conform to the specialized requirements of your process.

Our Product Family

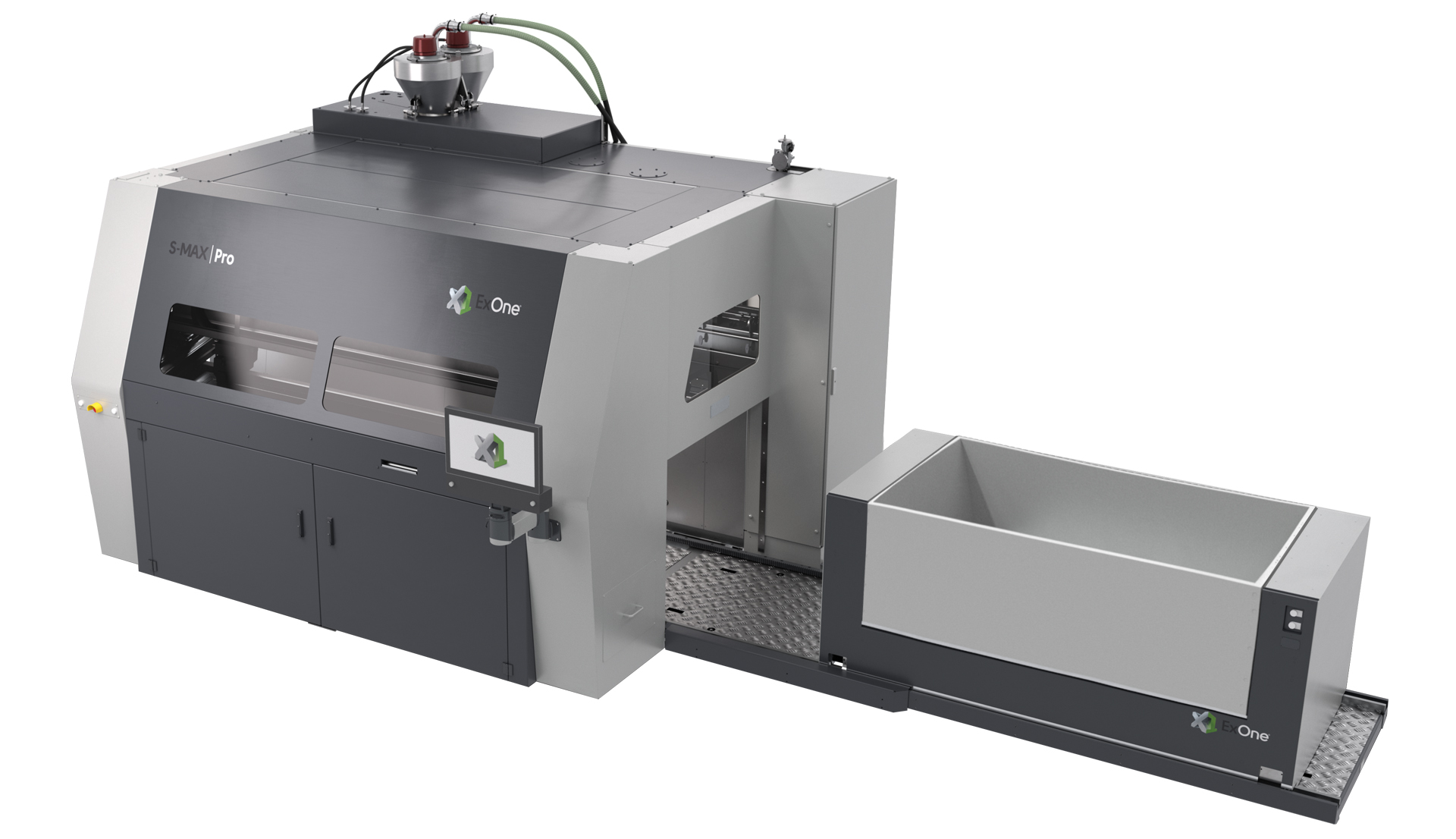

S-Max® Pro

The S-Max® Pro covers the full range of 3D sand printing from prototyping to serial production and is able to process all ExOne binder systems. It is available as a stand-alone solution but is also scalable and can be connected by a network that creates a fully automated production line, to realize the industrial serial production in 3D sand printing.

- Build Box 1,800 × 1,000 × 700* mm (70.9 × 39.4 × 27.6 in) (L × W × H)

- Build Volume 1,260 l (44 ft³)

- Max Build Rate Up to 145 l/h

- Layer Height 0.2 to 0.5 mm (200 to 500 μm)

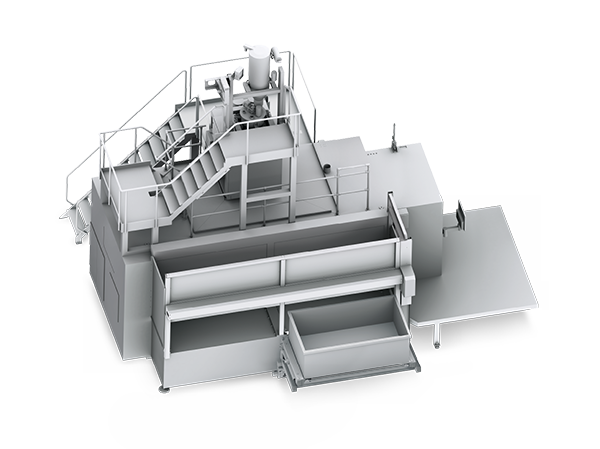

Exerial™

Series production of complex inorganic sand cores and molds is possible with the Exerial™ 3D printer, containing two job boxes.

- Build Box 2,200 x 1,200 x 700 mm

- Build Volume 2 x 1,848 L

- Max Build Rate 200 - 250 l/h

- Layer Height 0.3 mm

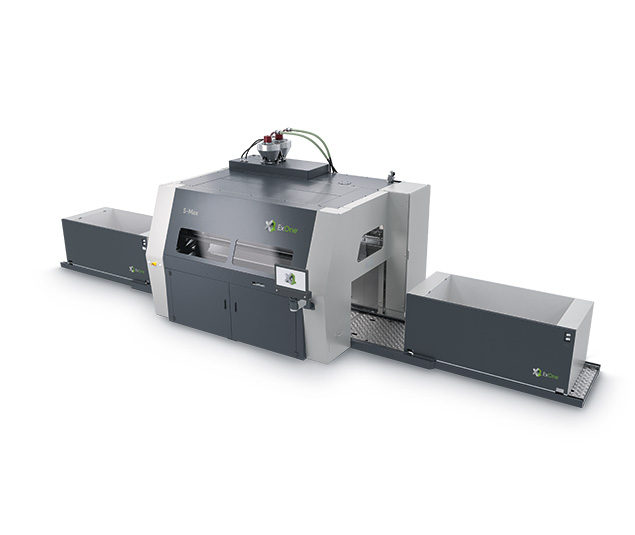

S-Max®

The S-Max® 3D core and sand mold system, ideally suited for sandcasting foundries, creates complex sand cores and molds directly from 3D CAD data, eliminating the need of a physical pattern. The ability to cast in hours without hard tooling improves the entire casting process chain. Realize new efficiencies with our largest build platform.

- Build Box 1,800 × 1,000 × 700 mm (70.9 × 39.4 × 27.6 in) (L × W × H)

- Build Volume 1,260 l (44 ft³)

- Max Build Rate Up to 125 l/h

- Layer Height 0.2 to 0.5 mm (200 to 500 μm)