- Home

- Parts & Services

Sand Parts on Demand

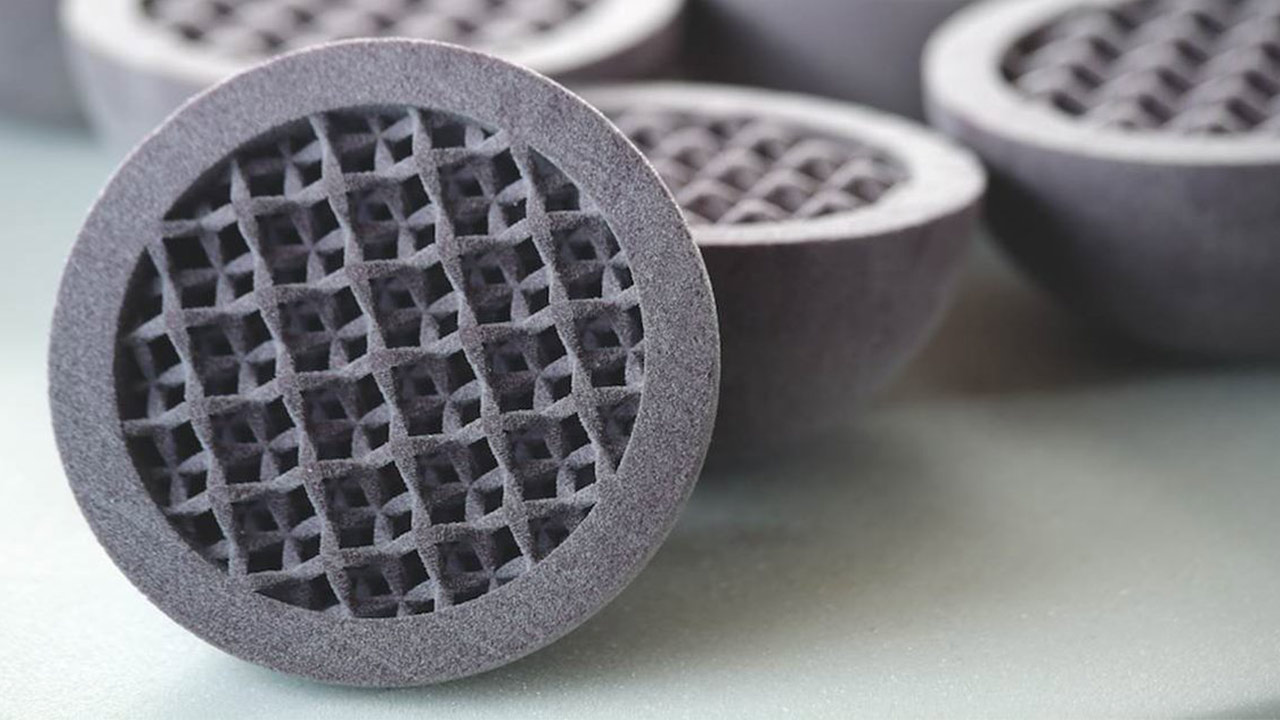

Sand Molds & Cores 3D Printed On Demand

Our global ExOne Adoption Centers support sandcasting mold and core prototyping and production as well as the development of infiltrated tooling applications, and our network of customers is ready to support your metalcasting needs.

Reduce Lead Time and Costs

If you’re looking to accelerate your product development and production timelines, 3D printing on-demand with ExOne technology can help provide the casting molds and cores you need for prototypes or serial production.

On-demand printing can create complex casting molds and cores on a tight schedule, helping bring products to market faster while maintaining detail and uniformity. With the digital workflow, binder jetting prints quickly from CAD files and we can help reverse-engineer and recreate casting molds and cores for lost patterns, outdated parts that are no longer available on the market, or replacement products with a high OEM price. Contact us to discuss your needs with our team and see how much time and budget sand 3D printing can save you.

On-Demand Sand Molds and Cores

Whether precision cores or molds with organic rigging features, sand 3D printing enables tooling-less castings with complex features and short lead times

Get started with 3d printed sand

Enhance Your Design to Achieve Done-In-One Castings

We offer a 360° range of services for high-value, complex parts. Our team has a unique combination of binder jetting and metalcasting expertise to support OEMs and foundries to innovate rigging designs and core geometries that increase casting quality.

Our team uses the freedom of design of additive manufacturing to produce more complex castings with intricate geometries, consolidated core assemblies, and organic rigging systems. We utilize virtual casting with solidification modeling allowing customers to iterate designs quickly without trial castings and optimize rigging and riser designs to enhance casting performance. Learn more about our OneCast services that support successful first pours.

3D Printers Ready for Your Project

Looking for a fast and convenient provider of premium sand molds and cores for your high-value or complex metalcasting project? ExOne's large and fast-growing network of industrial sand 3D printer owners use our proven binder jetting technology to provide complex molds and cores, typically within 3-5 days, for a wide range of cast materials.

FAQs for 3D Printed Sandcasting Molds and Cores

What are the benefits of binder jet 3D printing for sandcasting?

Molds and cores printed with ExOne binder jet technology enable faster delivery times, new design freedoms, and reduced costs by utilizing a digital, pattern-less workflow. OEMs and foundries are optimizing their production with binder jetting to deliver castings with complex rigging designs and monolithic cores in days, rather than weeks or months, while saving money on patterns, molds, and labor.

How do I know if 3D printed sand molds or cores will meet my needs?

ExOne offers Parts on Demand using either metal or sand binder jet printing systems, but our team of metalcasting experts also offer a detailed analysis of your application's requirements. We carry out virtual casting with solidification modeling to determine the successfulness of a pour, create unique rigging and riser designs to maximize the benefits of additive manufacturing, and, of course, offer 3D printing of cores, complex prototype molds, or production-scale casting molds.

Is assistance available to create a digital file?

ExOne accepts a wide range of digital modeling file types, though STL is most preferred. If you need assistance creating a file that is suitable for 3D printed molds, please contact us for support.

What materials/binder can I print with?

ExOne machines print a variety of silica and ceramic sand materials. These pair with our variety of binder systems, including inorganic binders, to tailor a print to the requirements of the casting. Reach out to our team to learn about the material options and which combination is right for your needs.

When will my parts be available?

We have on-demand sand printing facilities located in the North America, Europe, and Asia. Standard lead time for 3D printed sand molds and cores varies by location and may depend on the complexity of the casting mold or volume of the order. In the Americas our turnaround times are as fast as 3-5 days. Rush services are available, so reach out to get a custom quote for 3D printing.

Can you accommodate the volume of my order?

The binder jetting process for 3D printing sand casting molds suits applications with a lot of 1 or 1,000,000. At ExOne, we’re equipped to help you quickly develop a casting mold for a one-off prototype and its ensuing iterations, as well as produce 3D printed molds and cores at scale. We also have a network of customers who offer sand printing services we can connect you with to make sure you find the perfect fit for your production needs.

I have a high-value, complex casting. Can you help me ensure a successful first pour?

Our team has a unique combination of metalcasting and binder jetting experience to enable easy design changes, quick turnarounds, and successful first pours. Our OneCast range of services include a requirement analysis, rigging and riser design, fluid flow and solidification modeling, creating detailed pouring parameters, mold assembly instructions, and on-site pour supervision. OneCast saves customers time and money efficiently delivering complex castings right the first time.

Can sand binder jet 3D printing be used to create tooling?

Yes - ExOne binder jet machines create pre-forms for a range of tooling applications. Sacrifical tooling can be printed in unique shapes and used for composite layup where the sand is simply washed out after autoclaving. Additionally, the patented AMClad® process inflitrates and coats sand prints to create large tools able of withstanding various types of molding and forming processes, such as vacuum and hydroforming or sheet metal stamping.

On-Demand Sand Molds and Cores

Whether precision cores or molds with organic rigging features, sand 3D printing enables tooling-less castings with complex features and short lead times

Get Started with 3D printed sand